High Temperature Casters

Stephen Osburn2022-10-06T14:28:22-07:00High Temperature Casters

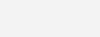

High Temperature Wheels with a prefix “NP” in the part number are made of nylon mixed with glass fiber. They perform best in moist heat applications such as in smokehouses, moist heat bakery and autoclave applications and around water and steam such a pressurized steam-autoclave. Temperature Rating: Up to 425° F for 30 minutes MAXIMUM continuous operation. Then allow to cool to room temperature. If used above 425° for more than 30 minutes continuous operation it will reduce the life of the wheel. High Temperature Glass-Filled Nylon wheels are not recommended for dry heat applications because once the moisture content of the wheel gets to zero, the wheel will shatter.

The High Temperature Phenolic Wheels ( prefix “TP” ) , the High Temperature Glass-Filled Nylon wheels ( prefix “NP” ), Wheels have a hard surface and should be used on smooth floor surfaces. If the floors are rough or if there are obstructions which will impact these wheels it will reduce the service life of the wheels. In any high temperature application it is always best to shield High Temperature Wheels from a direct heat intake source.

High Temperature Phenolic Wheels have a prefix “TP” in the part number and are made with glass fiber. They are best suited for dry heat applications such as powder coating, dry heat bakery ovens and dry heat autoclaves. Temperature Rating: Up to 475° F for 30 minutes MAXIMUM continuous operation. Then allow to cool to room temperature. If used above 475° F for more than 30 minutes continuous operation it will reduce the life of the wheel.

Consult us for a load capacity rating in your application. We will need the following information: Maximum Temperature and for how long? Maximum load on each caster? Is your application wet or dry?

-

Select optionsQuick View

Select optionsQuick View -

Add to cartQuick View

Add to cartQuick View -

Select optionsQuick View

Select optionsQuick View -

Select optionsQuick View

Select optionsQuick View

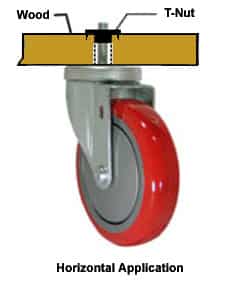

The above wheels with 1 1/4″ and 1 1/2″ tread width have plain bores and a bushing(s) to fit onto a 3/8″ axle. Wheels with a 2″ tread width have a 3/4″ ID Roller Bearing or Bronze Bearing and come with a steel spanner bushing to fit onto a 1/2″ axle. Some sizes are available with a 3/4″ Plain Bore upon request.