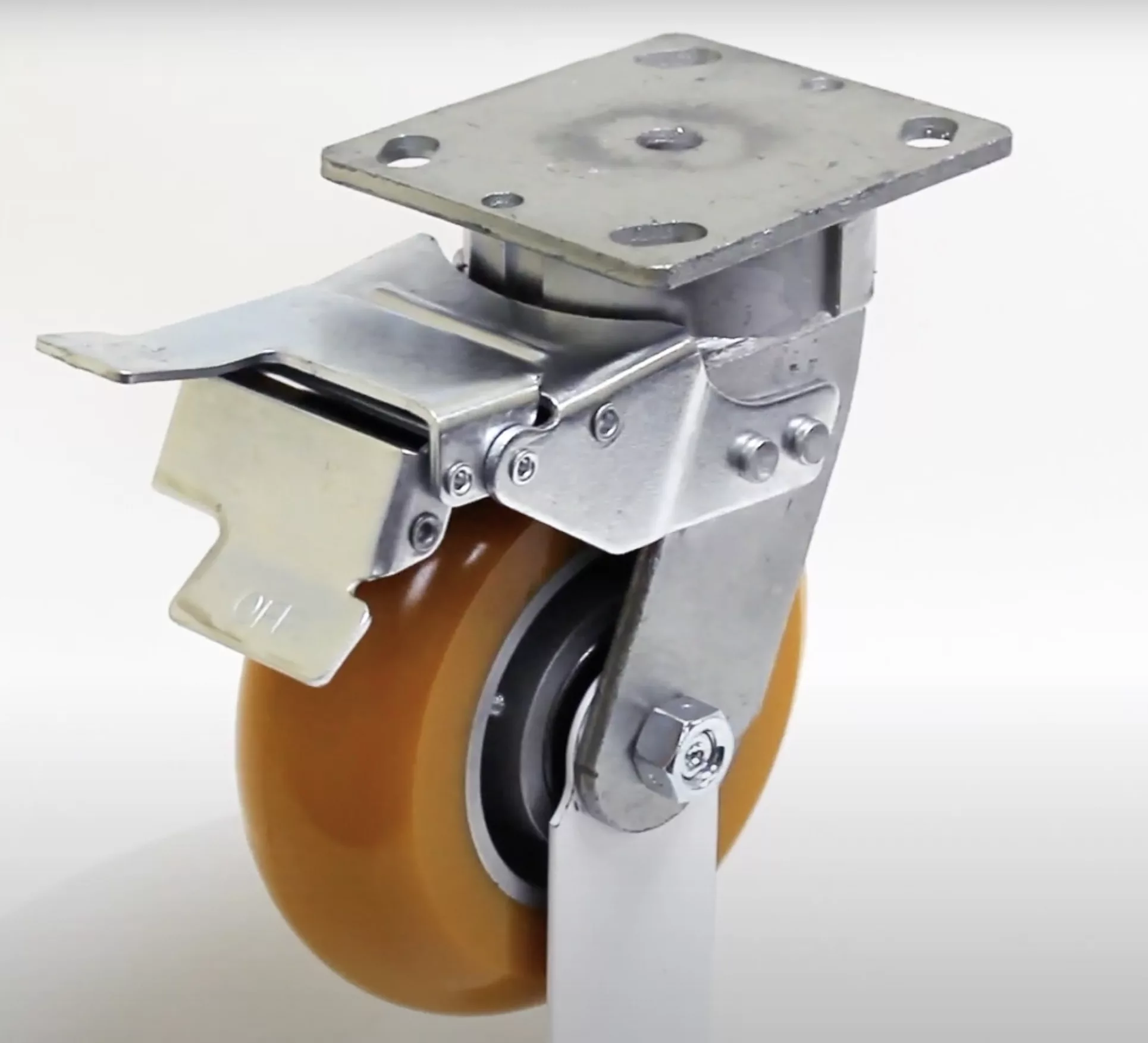

V Groove Caster Wheels

Stephen Osburn2023-11-27T15:01:16-07:00V Groove Caster Wheels

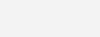

V-groove caster wheels are designed to guide equipment by rolling on inverted angle iron track. Elevated track minimizes problems caused by floor debris. The relief groove at the base of the “V” equalizes the load on each face of the angle. Forged Steel V-groove caster wheels minimize wear of the V-groove sides and are best for frequent operation. When not operating on track, the considerable wheel tread on each side of the V-groove allows for use on smooth floors. It is important that if more than one track is used they are parallel, straight and level. Otherwise V-groove wheels may bind or run up over the track. Tolerance should be within plus or minus 1/64″ every 20 feet. Joints between pieces of track should be smooth and well reinforced. V-groove caster wheels are standard with straight roller bearings, which allow only 1/16″ total end play (side to side movement). It is desirable when loads are great to use tapered bearings, which have thrust as well as radial capacity. The proper adjustment of tapered bearings prohibits end play.

Compression must be applied to properly seat tapered bearings. This is achieved by tightening down against a bearing spacer on each side of the wheel to a maximum looseness of .010. Since tapered bearings prohibit end play, their use requires parallel track. Unless the layout is nearly perfect, it is best to use a single angle iron track for V-groove caster wheels parallel to an elevated flat bed for wheels without a V-groove.

Solid Stainless wheels are standard with Stainless Roller Bearings and Spanner Bushings.

V-Groove Gray Iron Wheels perform well only if they are not exposed to any kind of abuse. Abuse includes things like shock loads, impact, poor floors or floor obstructions, overload, and use with mechanically powered equipment. We recommend only Ductile, Forged, or Machined Steel wheels for applications which may involve any kind of abuse. Call us first for a written recommendation before selecting any V-Groove Gray Iron wheel.

Wheels Chart (Click the Part Number to Order)

We do NOT include mounting Hardware.

Are you looking for a caster?

| WHEEL DLAM. | TREAD WIDTH | Wheel Color | Hub Length | Width of Groove | Depth of Groove | Max Cap. Lbs. | Wheel ONLY Part Number | Bearing I.D. / Type | I.D. with Spanner | Approx. Wt. |

|---|---|---|---|---|---|---|---|---|---|---|

| 4″ | 2″ | Gray Iron | 2 7/16″ | 7/8″ | 7/16″ | 500 | VL4x2 | 3/4″ Roller | 1/2″ | 3 3/4 |

| Ductile Steel | 2 7/16″ | 7/8″ | 7/16″ | 1500 | VS4x2 | 5 | ||||

| All Stainless | 2″ | 7/8″ | 7/16″ | 1500 | SSVG4x2 | 1/2″ Sealed SS Ball | 10 | |||

| Machined Steel | 2″ | 7/8″ | 7/16″ | 2000 | VMS4x2PS | 1/2″ P. Ball | NA | 5 | ||

| Glass Filled Nylon | 2 1/2″ | 7/8″ | 7/16″ | 500 | VN4x2PS | 1/2″ P. Ball | NA | 1 1/2 | ||

| 6″ | 2″ | Gray Iron | 2 7/16″ | 7/8″ | 7/16″ | 500 | VL6x2 | 3/4″ Roller | 1/2″ | 6 |

| Ductile Steel | 2 7/16″ | 7/8″ | 7/16″ | 1500 | VS6x2 | 8 | ||||

| All Stainless | 2″ | 7/8″ | 7/16″ | 1500 | SSVG6x2 | 21 | ||||

| Machined Steel | 2″ | 7/8″ | 7/16″ | 3000 | VMS6x2PS | 1/2″ P. Ball | 1/2″ | 11 | ||

| 2 1/2″ | Ductile Steel | 2 3/4″ | 7/8″ | 7/16″ | 3500 | VS6x2.50N | 1″ Roller | 3/4″ | 11 | |

| 3″ | Gray Iron | 3 1/4″ | 7/8″ | 7/16″ | 1000 | VL6x3 | 1″ Roller | 3/4″ | 12 | |

| Ductile Steel | 3 1/4″ | 7/8″ | 7/16″ | 5000 | VS6x3 | 15 | ||||

| Ductile Steel | 3 1/2″ | 7/8″ | 7/16″ | 7000 | VS6x3T.75T | 3/4″ Tapered | NA | 15 | ||

| Ductile Steel | 3 1/2″ | 1 3/8″ | 11/16″ | 7000 | VS6x3W.75T | 15 | ||||

| Ductile Steel | 3 1/2″ | 7/8″ | 7/16″ | 8000 | VS6x3T-1T | 1″ Tapered | 12 | |||

| Ductile Steel | 3 1/2″ | 1 3/8″ | 11/16″ | 8000 | VS6x3W-1T | 15 | ||||

| 8″ | 3″ | Ductile Steel | 3 1/4″ | 7/8″ | 7/16″ | 5000 | VS8x3 | 1″ Roller | 3/4″ | 22 |

| 4″ | Forged Steel | 4 1/2″ | 1 3/4″ | 11/16″ | 15,000 | VF8x4-1.25T | 1 1/4″ Tapered | NA | 37 | |

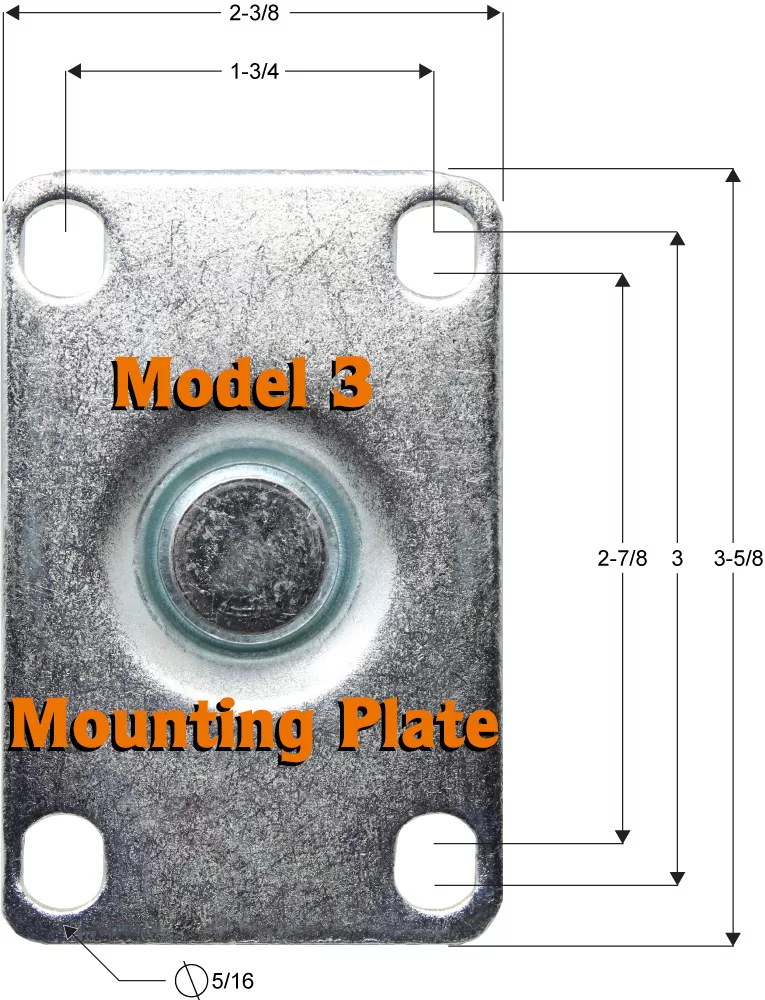

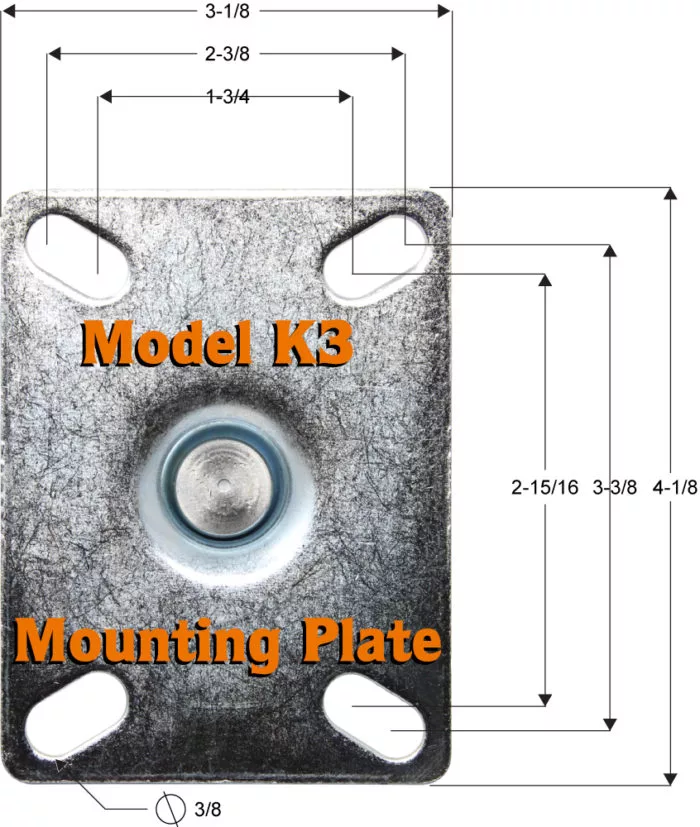

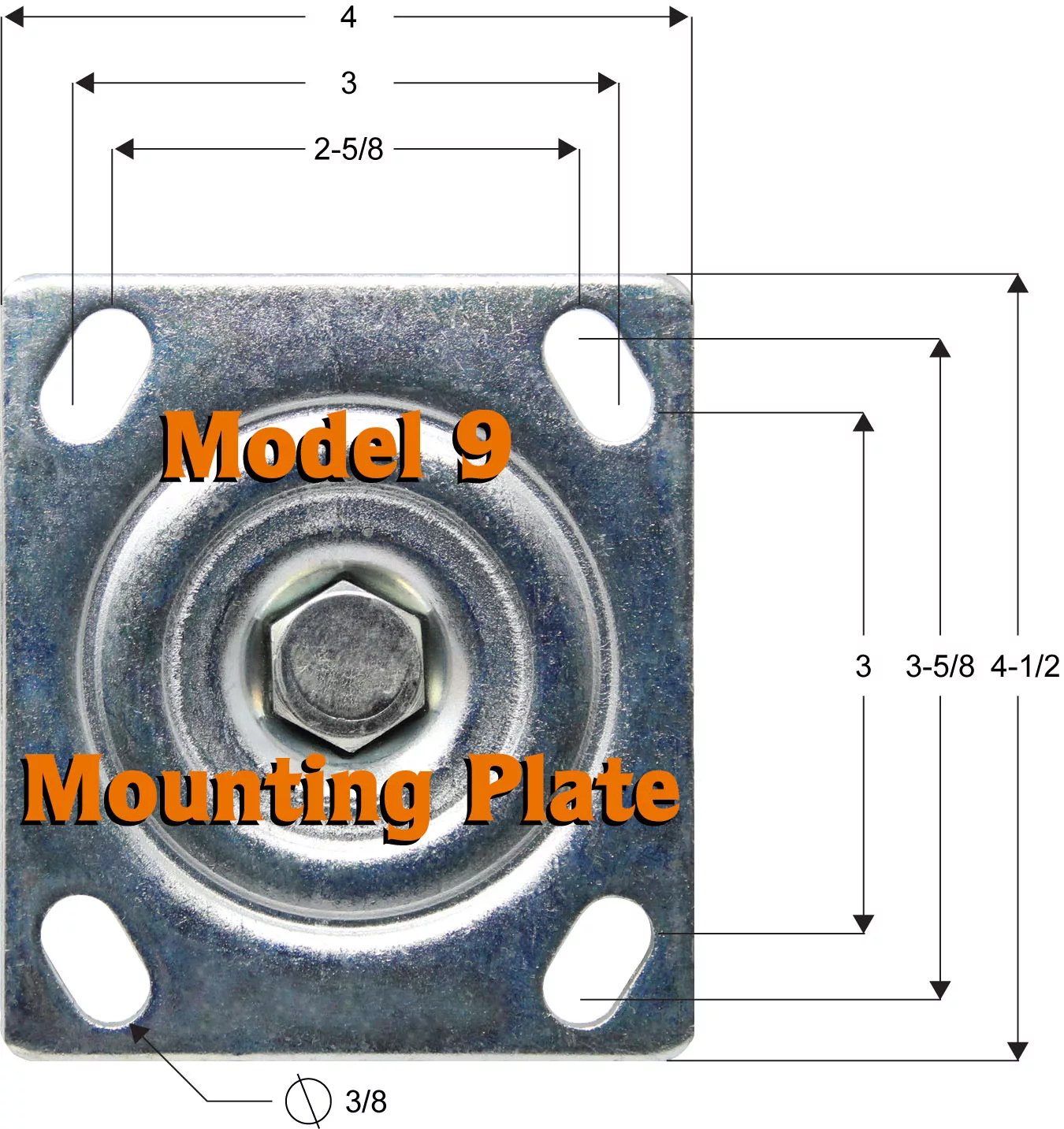

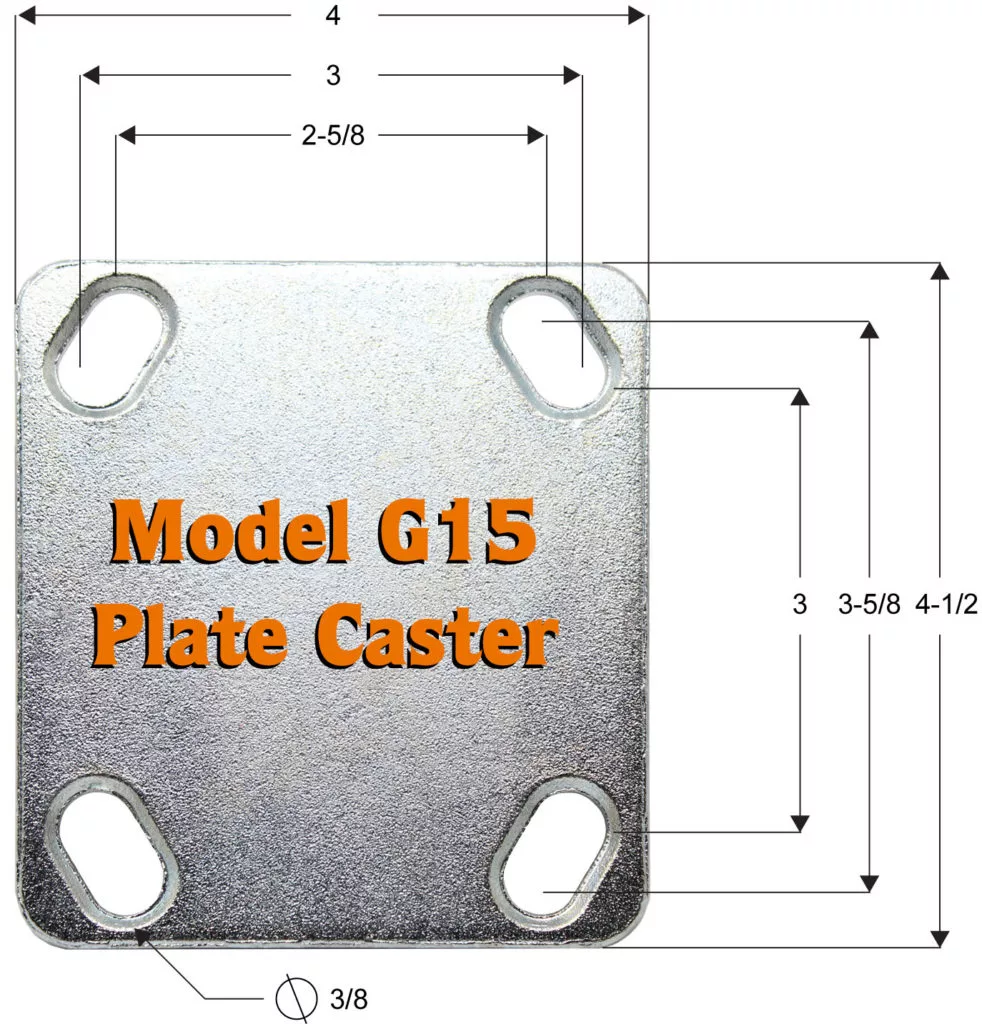

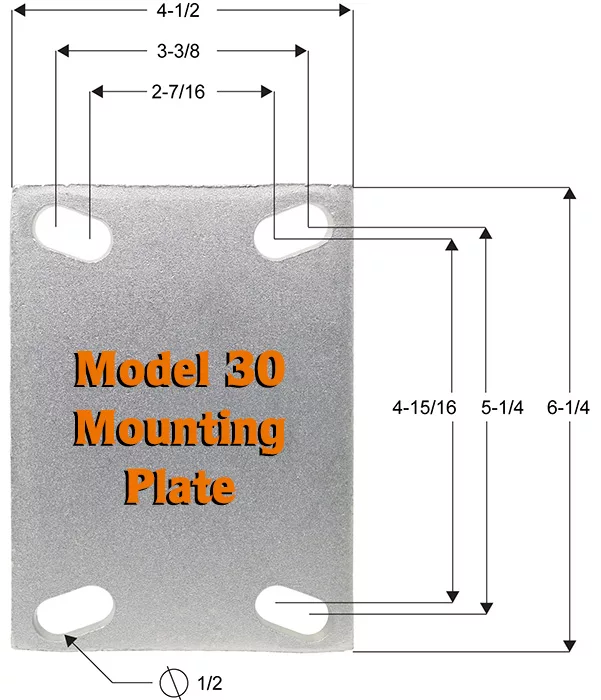

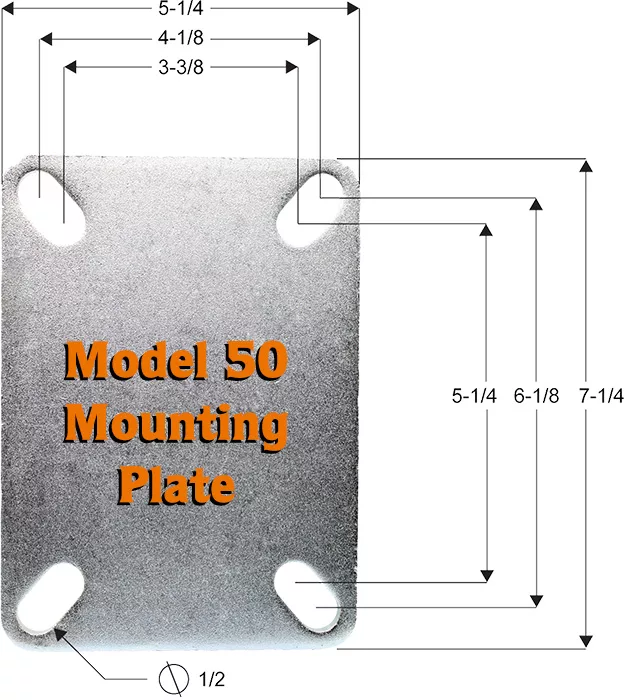

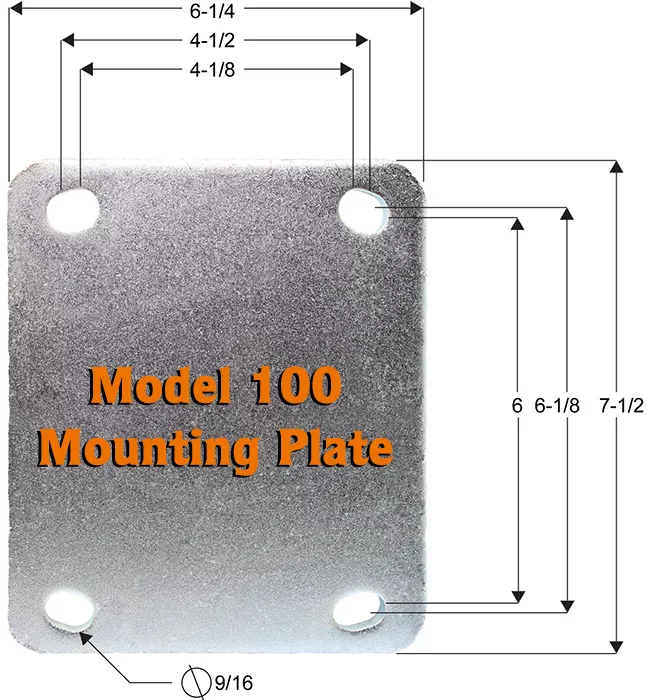

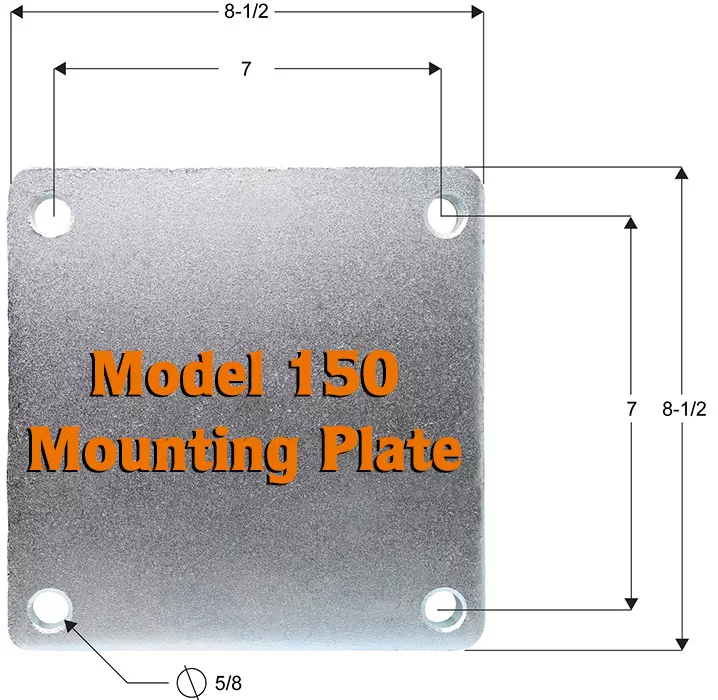

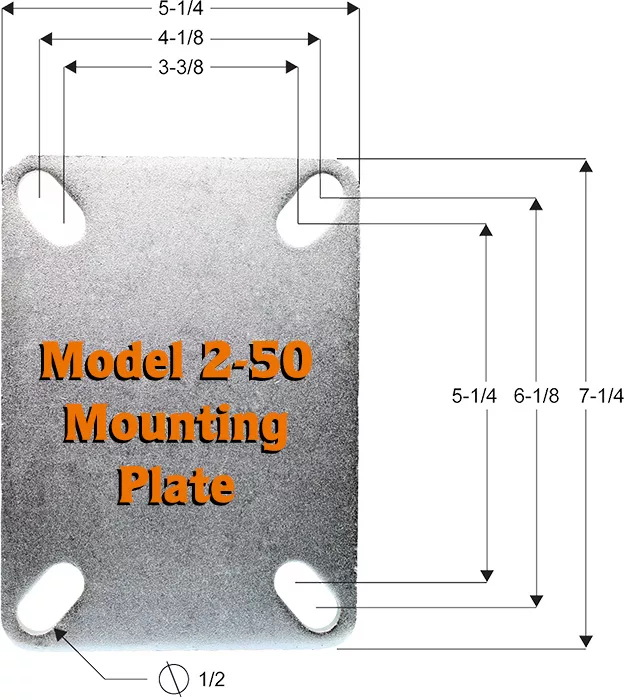

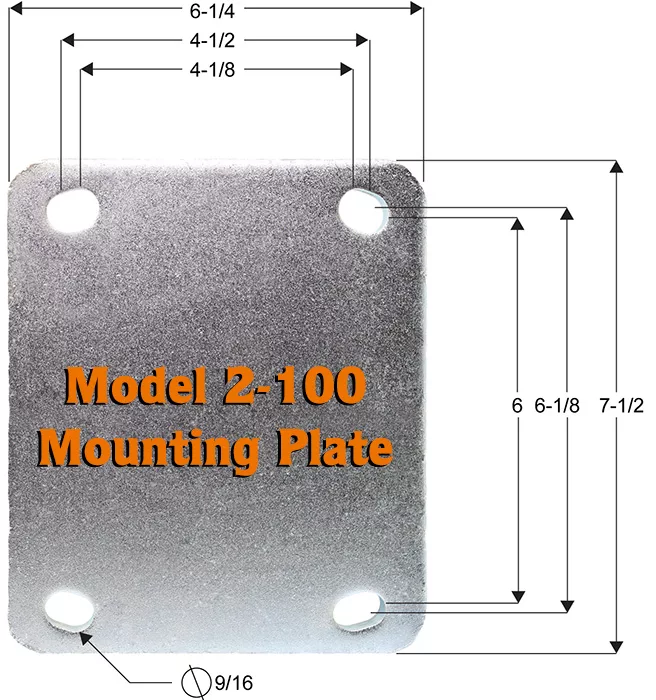

Typical Installation Dimensions

- “VL” indicate Gray Iron V-Groove Caster Wheels.

- “VF” indicate Forged Steel V-Groove Caster Wheels.

- “VS” indicates Ductile Steel V-Groove Caster Wheels.

- “APV” indicates All Polyurethane V-Groove Caster Wheels.

- “SSVG” indicates All Stainless Steel V-Groove Caster Wheels.

You should never select on the basis of load capacity alone. Capacity ratings do not take into account the effort required to manually move a load. Capacity ratings are based on manual operation under ideal conditions. If these wheels are going to be moved by mechanically powered equipment, consult us for a reduced capacity rating based on your application.