6″ x 3″ – V Groove Forged Steel Wheel – 1″ Tapered Roller Bearing

$299.36

Technical Specifications

Description

Where loads are too heavy for floor protective wheels, or where unusually severe service factors are present, forged steel industrial caster wheels will do the job. Forged steel wheels have the highest ductility and tensile strength of any industrial caster wheel that we manufacture. Caster City counter bores each side of the hub and presses in 2 tapered roller bearings to offer maximum capacity and service life. Forged steel industrial caster wheels will damage most factory floors while under heavy loads, and thus are generally used on steel plate, in channel, or as v-grooved wheels rolling on an inverted angle iron track.

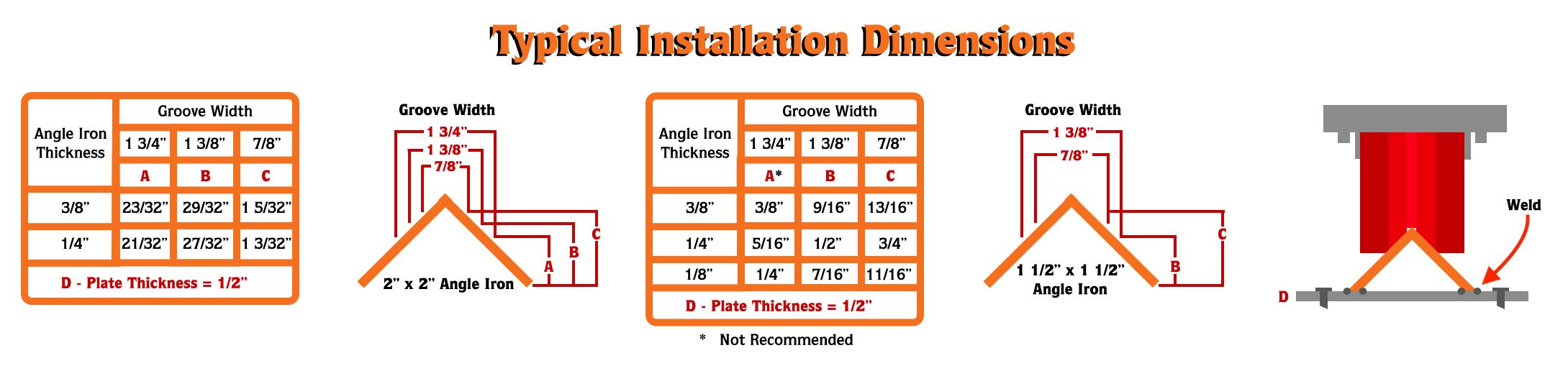

6″ x 3″ – V Groove Forged Steel Wheel. Caster City’s V-groove forged steel caster wheels are designed to guide equipment by rolling on inverted angle iron track. Caster City leaves behind enough wheel tread material on v-groove industrial caster wheels to allow them to be used on smooth surfaces when not on a track. Caster City provides a lubrication fitting on all v-groove industrial caster wheels. Caster City offers v-groove industrial caster wheels with either a tapered roller bearing, precision sealed ball bearings, or roller bearings. Caster City manufactures forged steel industrial wheels in 2”, 3”, and 4” wide and in diameters ranging from 6” to 12”. Temperature ranges for v-groove industrial caster wheels mirror that of typical steel wheels and can go up to 1300 degrees Fahrenheit with a high-temperature bronze bearing.

Real-World Applications for V-Groove Caster Wheels on Tracks

- Automotive Manufacturing:

- Moving vehicle parts (e.g., frames, chassis) along tow-line systems in assembly lines, ensuring precise alignment and efficient production flow.

- Guiding carts in paint booths for car body painting, maintaining consistent positioning during the process.

- Aerospace Industry:

- Transporting aircraft components (e.g., wings, fuselage sections) on tracks in assembly areas, providing stable, guided movement for heavy, precision parts.

- Moving rocket modules through production or testing facilities, ensuring controlled handling.

- Boat and Yacht Building:

- Guiding hulls and molds along tracks during construction, supporting heavy loads with precise movement to maintain alignment in shipyards.

- Observatories:

- Moving telescope roofs on tracks, allowing for smooth, guided motion to open or close observatory domes with exact positioning.

- Heavy Manufacturing:

- Transporting oversized machinery or components (e.g., industrial presses, CNC machines) along production lines, ensuring stable movement on tracks.

- Moving heavy equipment between machines in factories, maintaining a controlled path for efficient workflow.

- Steel Mills:

- Guiding carts carrying molten metal or steel products on tracks, handling extreme loads and abusive conditions like impacts or high temperatures.

- Transporting steel beams or plates along production lines, ensuring precise movement in harsh environments.

- Food Processing:

- Moving baked goods into ovens on tracked carts, ensuring clean, guided transport in production lines.

- Guiding food products (e.g., packaged goods) along tracks in processing plants, maintaining efficiency and hygiene.

- Warehouses and Distribution Centers:

- Transporting heavy goods (e.g., pallets, large crates) on tracks over long distances, ensuring efficient material flow in high-traffic areas.

- Guiding carts or conveyors in automated distribution systems, maintaining alignment for seamless operations.

- Paint Lines:

- Moving products (e.g., machinery parts, vehicles) through painting processes on tracks, ensuring consistent positioning for uniform coating application.

- Assembly Tracks:

- Guiding components along assembly lines in various industries (e.g., electronics, appliances), ensuring precise sequencing and efficient production.

- Moving sub-assemblies between workstations in manufacturing plants, maintaining controlled flow.

- Mining Operations:

- Guiding mine carts on tracks to transport ore or equipment, particularly with ductile steel V-groove wheels to handle rough conditions (though less common, as flanged wheels are often preferred in traditional mining setups).

- Textile Industry:

- Moving machinery or material carts on tracks in textile production facilities, ensuring controlled motion for heavy looms or fabric rolls (niche application, dependent on specific track setups).

- Defense and Military:

- Transporting heavy equipment or fortifications (e.g., mobile helipads, weapon systems) on tracks, ensuring precise movement in rugged environments.

- Guiding carts for munitions or vehicle components in military assembly areas, supporting high loads with stability.

- Construction Sites:

- Moving heavy construction materials (e.g., steel beams, concrete panels) on temporary tracks, providing guided transport in rough terrain (requires ductile steel for impact resistance).

- Pharmaceutical and Cleanroom Environments:

- Guiding carts with sensitive equipment or materials on tracks in cleanrooms, ensuring controlled movement without floor debris interference (stainless steel V-groove wheels with stainless roller bearings are ideal for corrosion resistance).

Our #1 goal is to help you find the best caster and wheels for your needs. If you need help finding the right casters, contact our team of professionals. You can also customize many of our casters with a variety of options such as swivel locks, wheel brakes and zerk fittings. We ship our products from assembly plants in Georgia, Pennsylvania, Virginia, Texas, Nevada and Canada. Whether you’re a one-man shop or a global giant, we can provide you with: We specialize in Business to Business, however, consumer orders are gladly accepted and we can provide you with:

Our #1 goal is to help you find the best caster and wheels for your needs. If you need help finding the right casters, contact our team of professionals. You can also customize many of our casters with a variety of options such as swivel locks, wheel brakes and zerk fittings. We ship our products from assembly plants in Georgia, Pennsylvania, Virginia, Texas, Nevada and Canada. Whether you’re a one-man shop or a global giant, we can provide you with: We specialize in Business to Business, however, consumer orders are gladly accepted and we can provide you with:

- Fastest Lead Time in the Industry

- Caster performance data.

- Comparative data.

- Customized caster solutions.

- Help with caster solutions.

- Case studies by industry or application.

- Manufacturer and Distributor of over $25 million dollars in Finished Component Parts

- Majority of Orders Processed and Shipped in 2 Days or Less