FREE NEXT DAY DELIVERY*

* On Business Days - Purchases $100 or More

30% OFF $200* Use Code: PORTOCARS

Online Purchases Only

* Minimal Purchase Price

- Shop

- Plate Casters

- Compare Your Plate Size to Ours

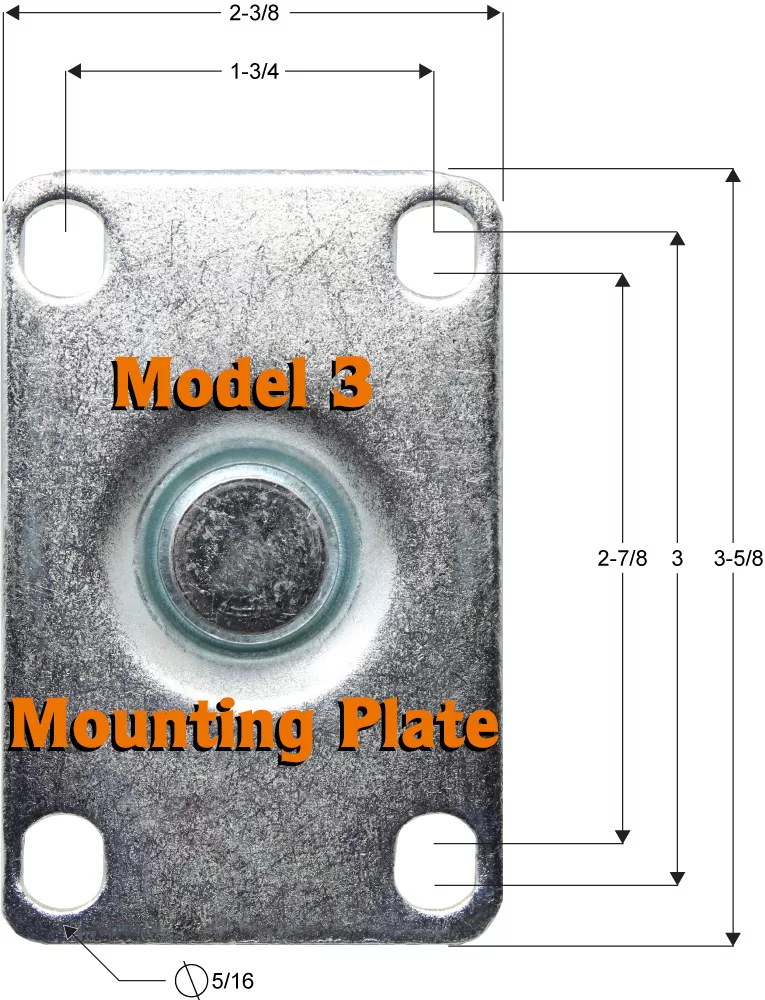

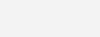

- Model 3 – Up To 350lbs – 3″ thru 5″ Wheels – Plate Size 2-3/8″ x 3-5/8″

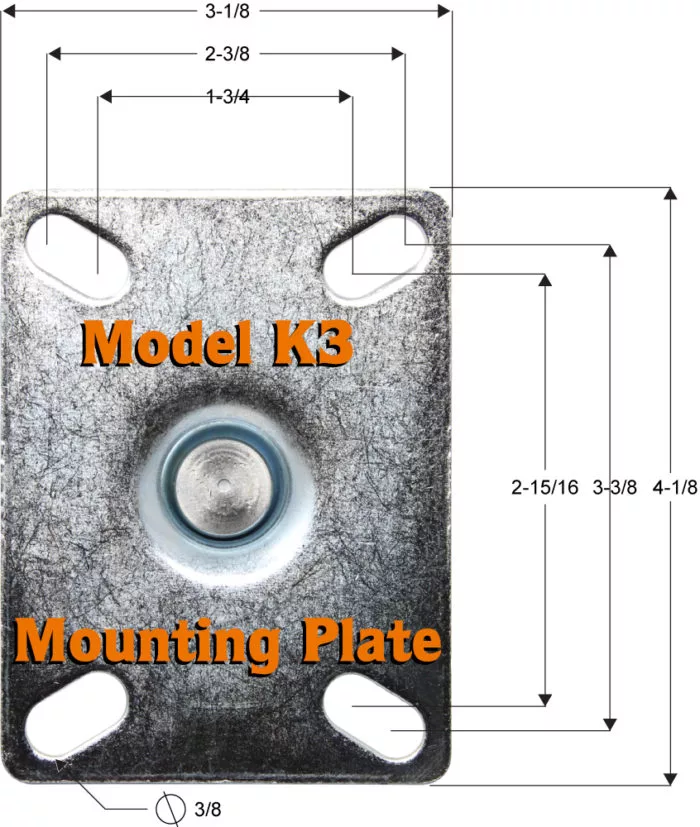

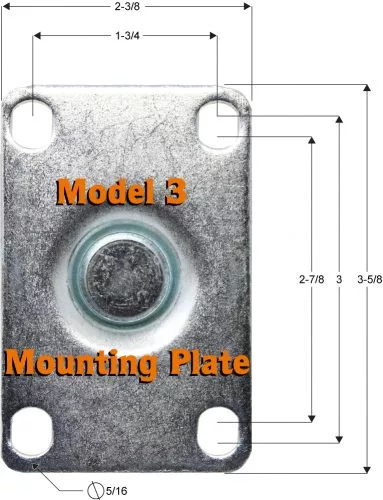

- Model K3 – Up to 350 lbs – 3″ thru 5″ Wheels – Plate Size 3-1/8″ x 4-1/8″

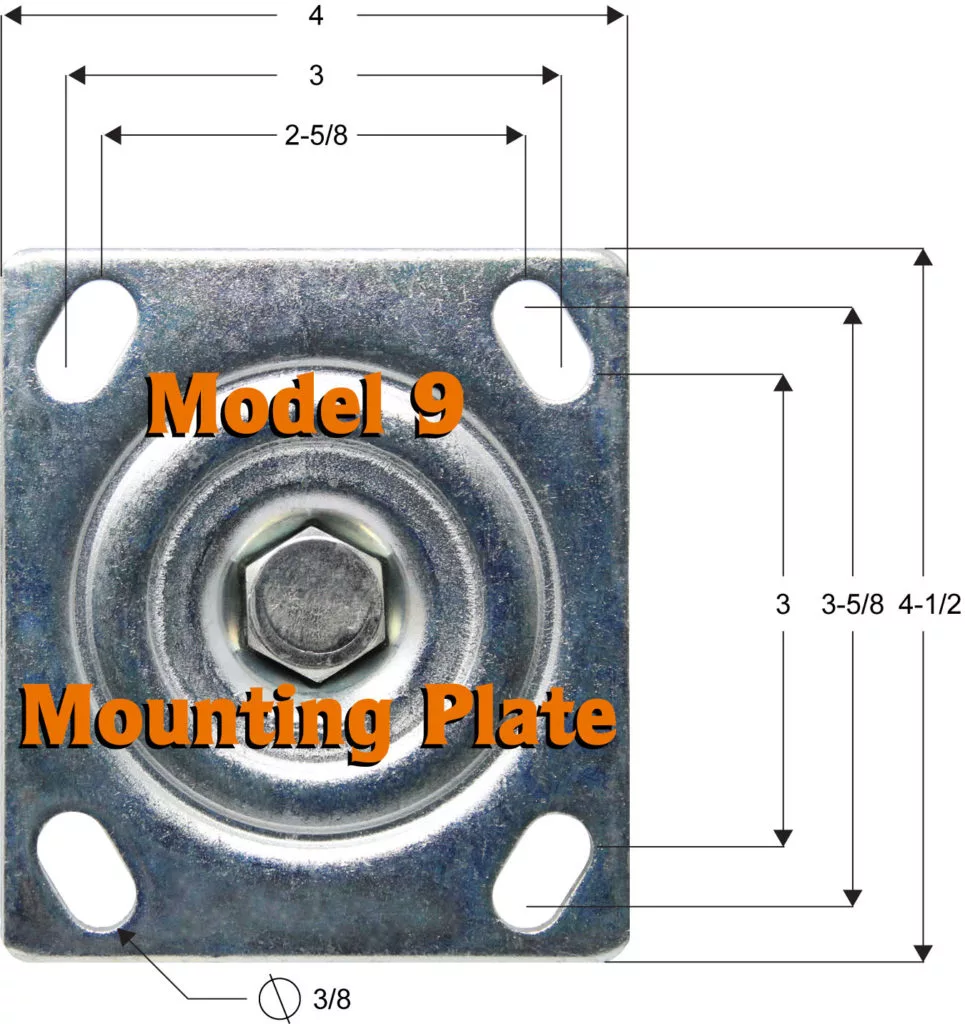

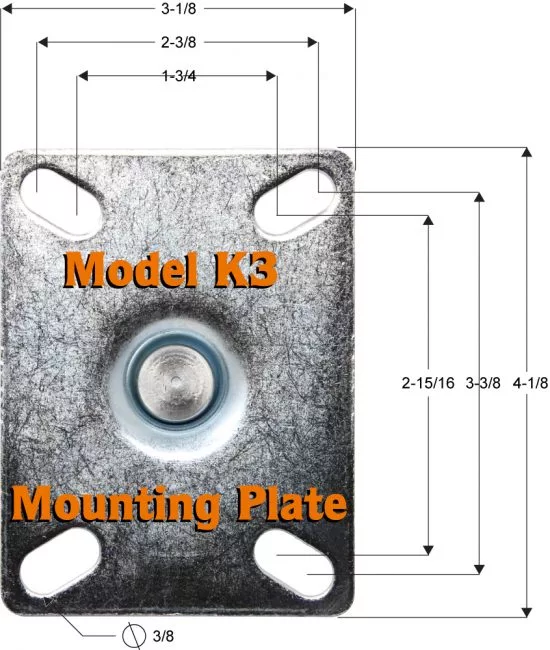

- Model 9 – Up To 1,200lbs – 3-1/4″ thru 8″ Wheels – Plate Size 4″ x 4-1/2″

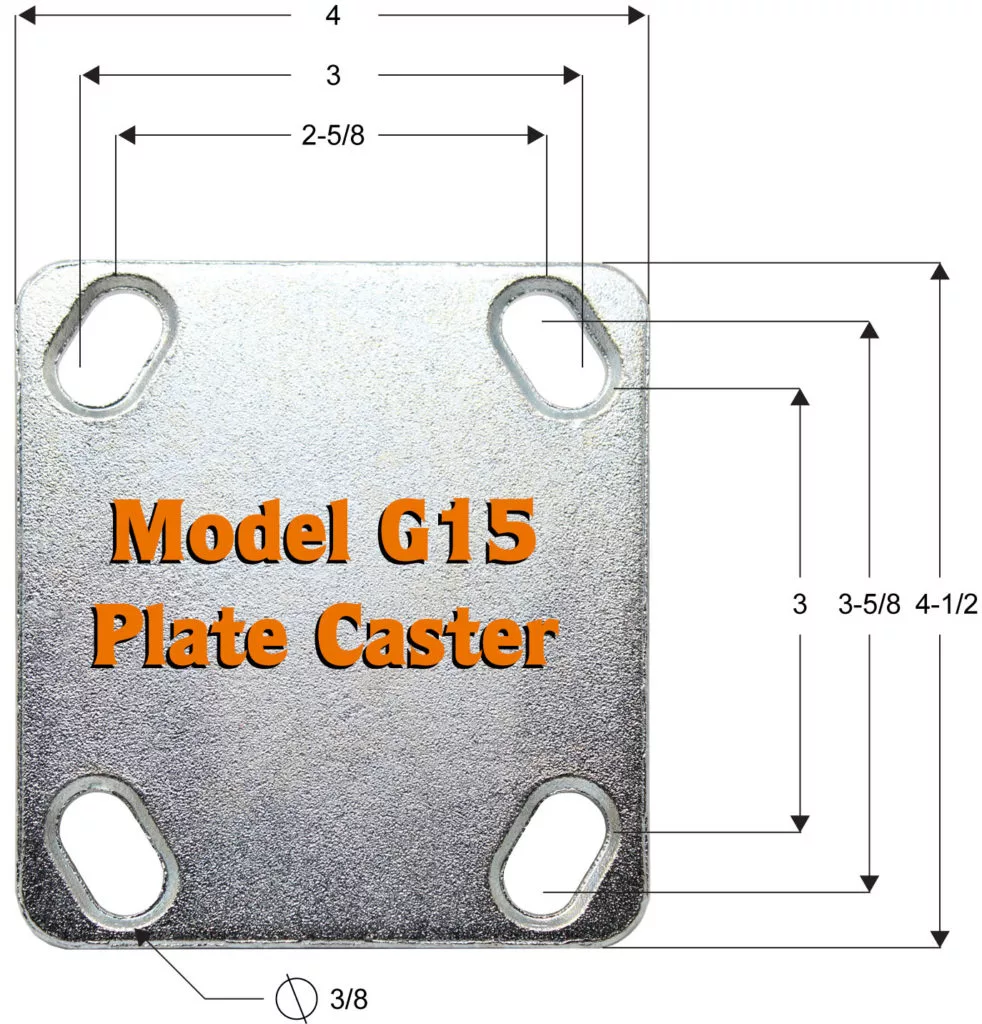

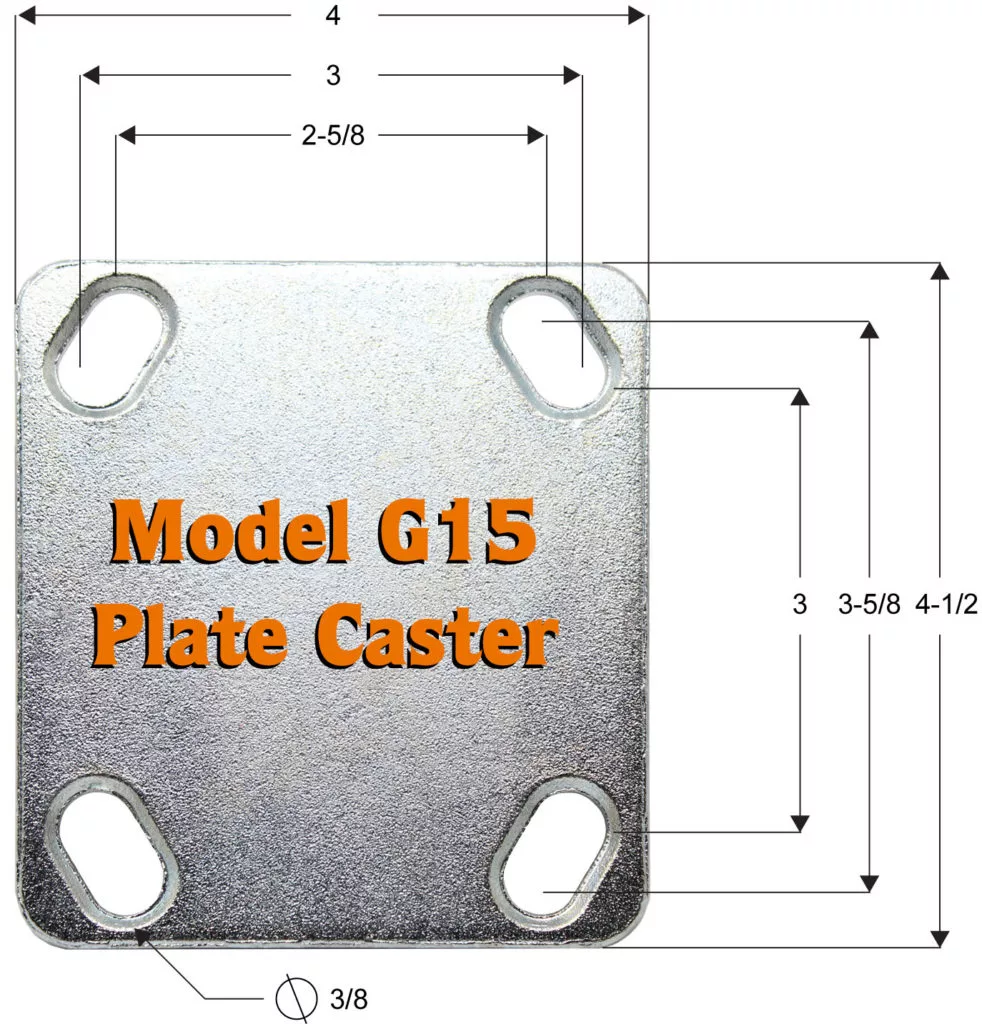

- Model G15 – Up To 2,000lbs – 4″ thru 8″ Wheels – Plate Size 4″ x 4-1/2″

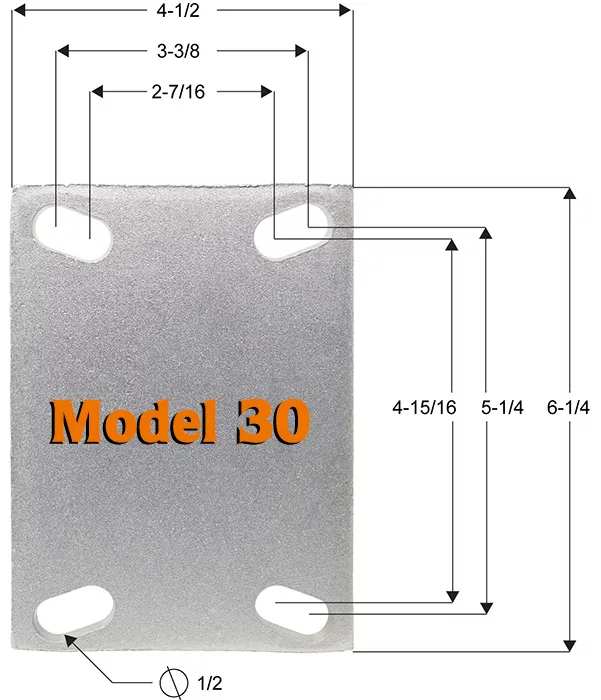

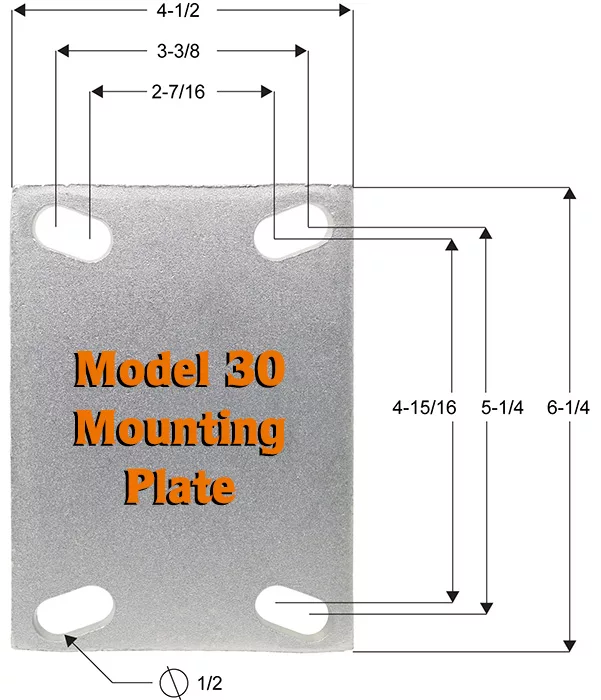

- Model 30 – Up To 4,000lbs – 6″ thru 10″ Wheels – Plate Size 4-1/2″ x 6-1/4″

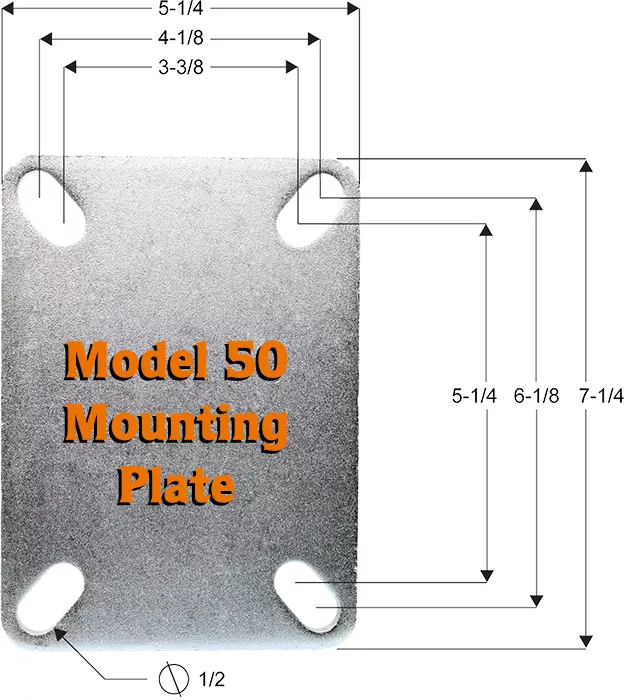

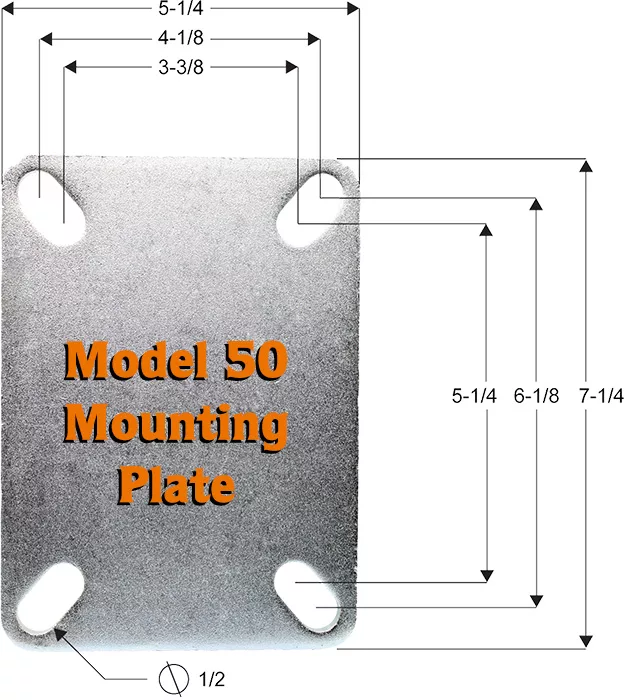

- Model 50 – Up To 7,000lbs – 6″ thru 12″ Wheels – Plate Size 5-1/4″ x 7-1/4″

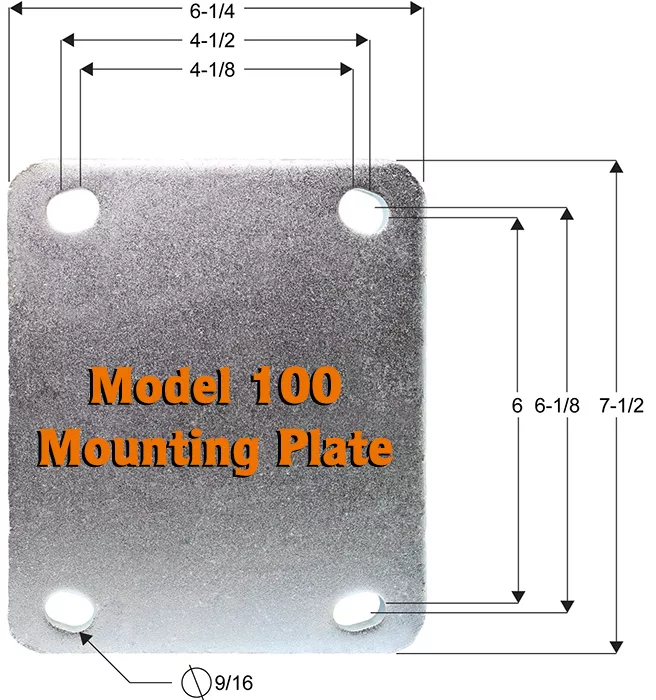

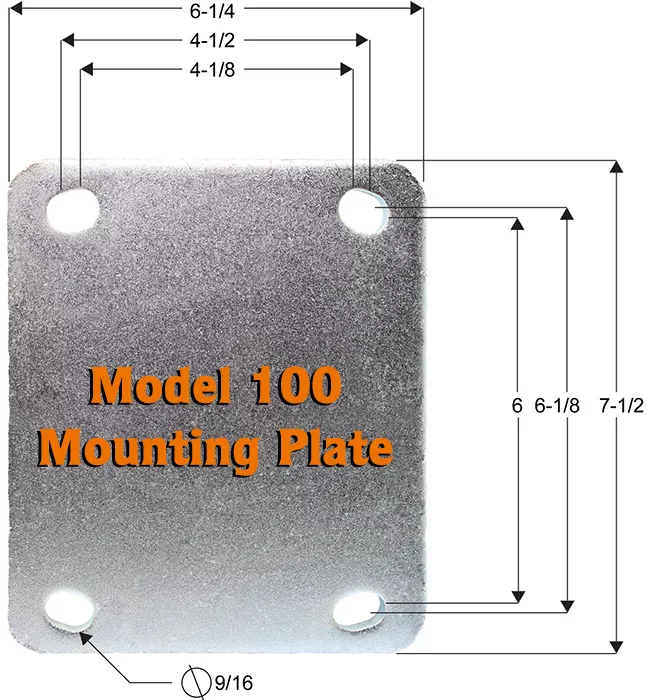

- Model 100 – Up To 15,000lbs – 6″ thru 12″ Wheels – Plate Size 6-1/4″ x 7-1/2″

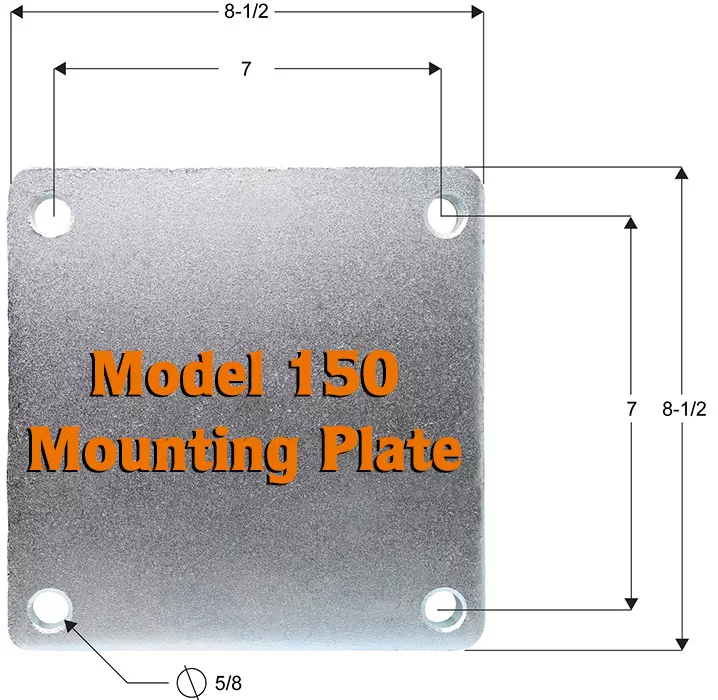

- Model 150 – Up To 20,000 lbs – 8″ thru 12″ Wheels – Plate Size 8-1/2″ x 8-1/2″

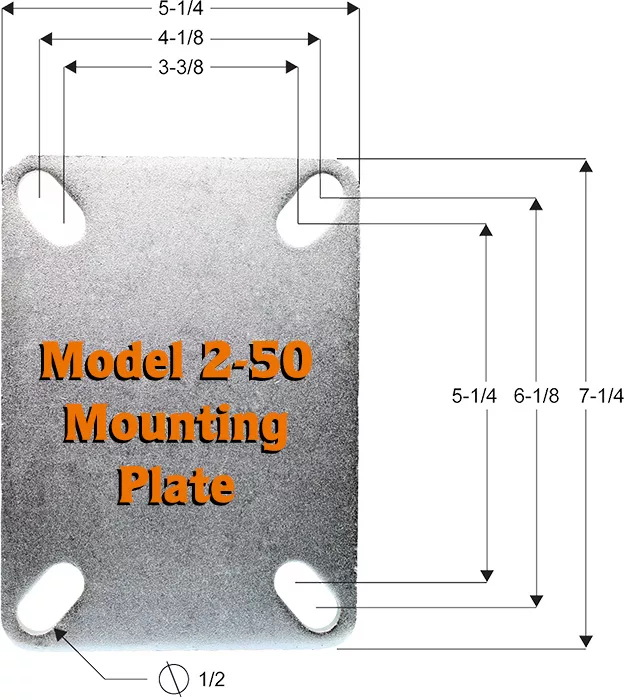

- Model 2-50 – Up To 7,000lbs – 6″ thru 12″ Wheels – Plate 5-1/4″ x 7-1/4″

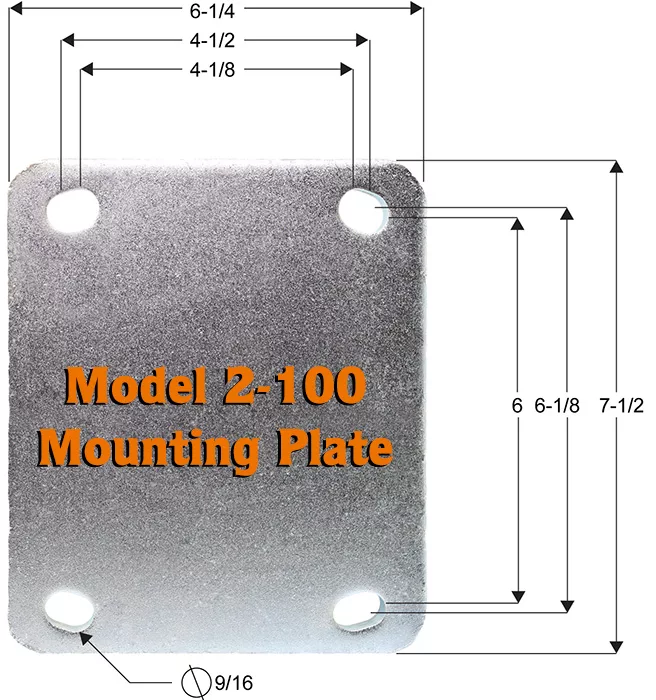

- Model 2-100 – Up To 20,000lbs – 8″ thru 12″ Wheels – Plate 6-1/4″ x 7-1/2″

- Model 2-150 – Up To 40,000lbs – 8″ thru 12″ Wheels – Plate 8-1/2″ x 8-1/2″

- Stem Casters

- VIEW ALL Stem Casters by Stem Type – CLICK HERE

- Threaded Stem Casters (Diameter)

- Expanding Rubber Stem

- Stem Caster Model 3 – up to 300lbs

- Total Locking Casters – Stem Caster Model 3A – up to 300lbs

- Total Locking Casters – Stem Caster Model K3A – up to 300lbs

- Stainless Steel Stem Caster Model 3 – up to 300lbs

- Economy Stainless Steel Stem Caster Model K3 – up to 300lbs

- Total Locking Casters – Stainless StemCaster Model 3A

- Stemless / Hollow Kingpin

- Grip Ring Stem

- Square & Round Metal Stem

- Stainless Steel Stems

- T-Nuts

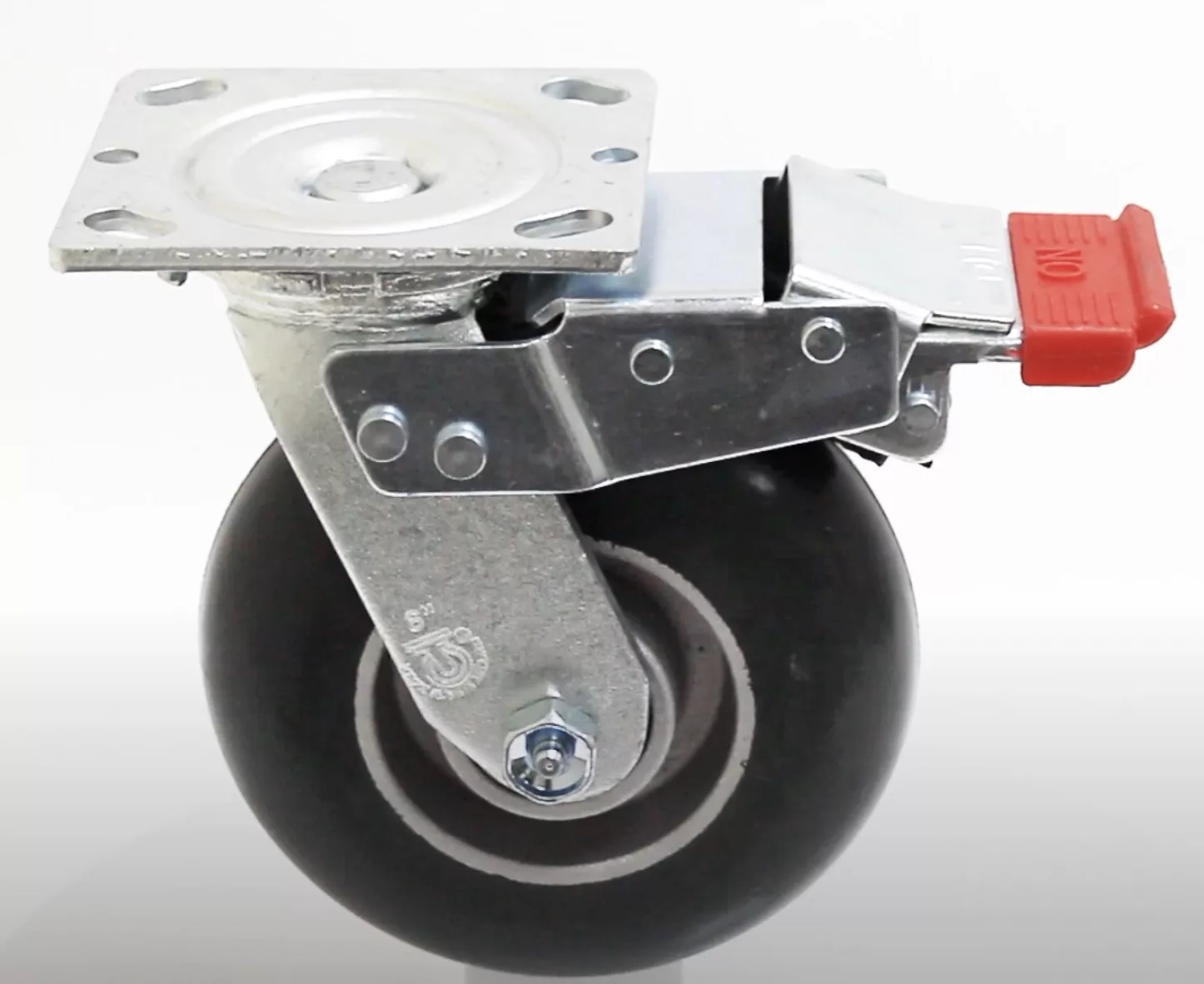

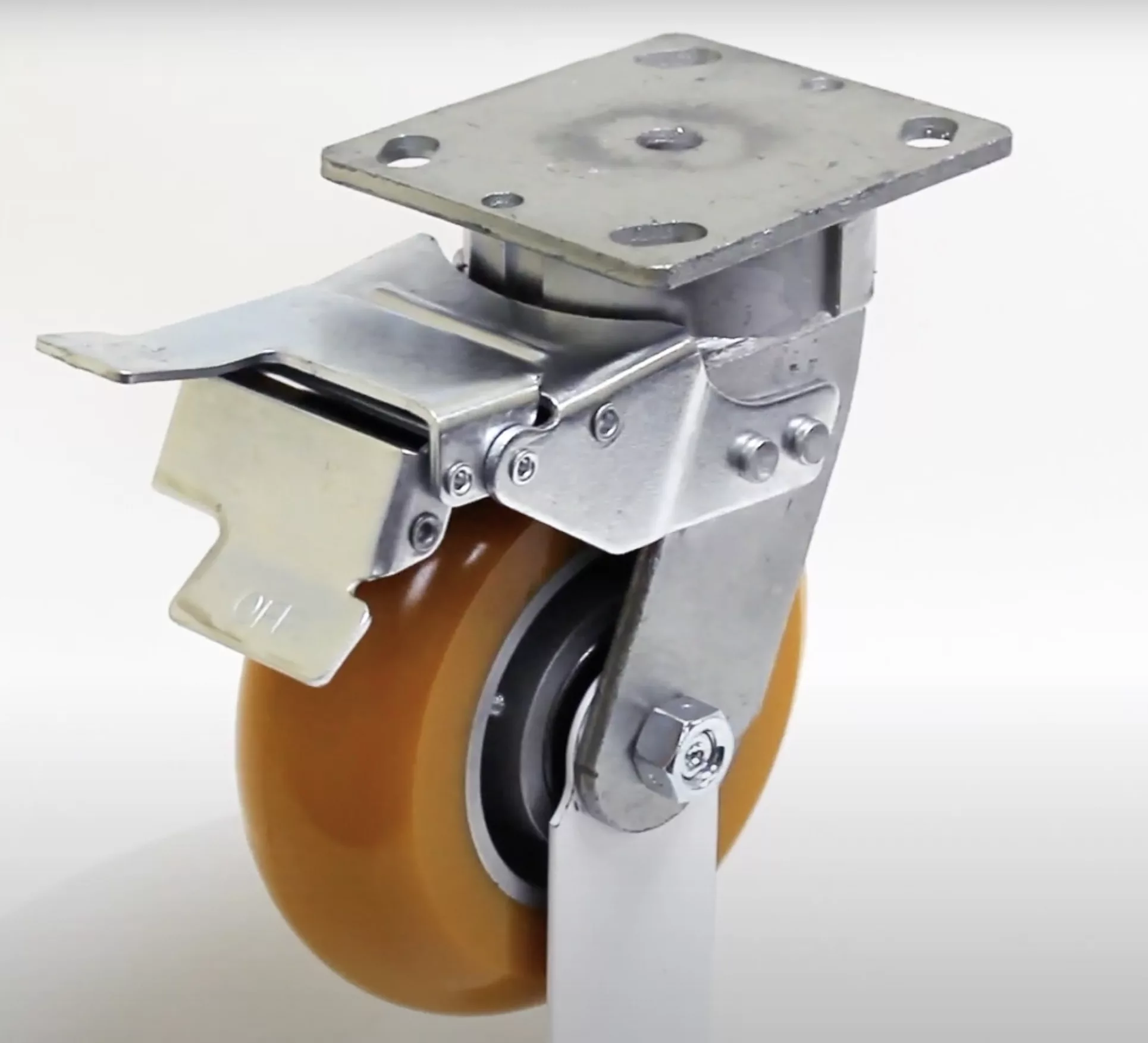

- Total Locking Brake Casters

- Total Locking Plate Casters Information

- Total Locking Stem Casters Info Page

- Total Locking Plate Casters

- Dual Wheel Casters – up to 200lbs

- Plate Caster Model K3A Up To 350lbs – 3″ thru 5″ Wheels – Plate Size 2-3/8″ x 3-5/8″ – NYLON PEDAL

- Plate Caster Model 3A Up To 350lbs – 3″ thru 5″ Wheels – Plate Size 2-3/8″ x 3-5/8″ – METAL Pedal

- STAINLESS STEEL Plate Caster Model 3A – up to 300 lbs – 3″ thru 5″ Wheels – Plate Size 2-3/8″ x 3-5/8″

- Plate Caster Model 9 – up to 1200 lbs – 4″ thru 8″ Wheels – Plate Size 4″ x 4-1/2″

- Plate Caster Model G15 – up to 2000 lbs – 4″ thru 8″ Wheels – Plate Size 4″ x 4-1/2″

- Total Locking Stem Casters

- Stainless Steel Casters

- Plate

- Stainless Steel Plate Caster Model SS-3 – up to 300lbs – 3″ thru 5″ wheels – Plate Size 2-3/8″ x 3-5/8″

- Stainless Steel Economy Plate Caster Model SS-K3 – up to 300lbs – 3″ thru 5″ wheels – Plate Size 2-3/8″ x 3-5/8″

- Total Locking Brake Model SS-3A – up to 300lbs – 3″ thru 5″ wheels – Plate Size 2-3/8″ x 3-5/8″

- Stainless Steel Model SS-9 – up to 900lbs – 4″ thru 8″ Wheels – Plate Size 4″ x 4-1/2″

- Stainless Steel Model SS-G15 – up to 1500lbs – 4″ thru 8″ Wheels – Plate Size 4″ x 4-1/2″

- Stainless Steel Plate Caster Model 30 – up to 3000lbs – Plate Size 4-1/2″ x 6-1/4″

- Stainless Steel Plate Caster Model 50 – Up to 3000lbs – Plate Size 5-1/4″ x 7-1/4″

- Heavy Duty / Extreme Duty Stainless Steel Kingpinless Casters

- Stem

- Stainless Steel Stem Caster Model SS-3 – up to 300lbs – (1/2″ – 3/4″)

- Economy Stainless Steel Stem Caster Model SS-K3 – up to 300lbs – (1/2″ – 3/4″)

- Total Locking Stainless Stem Caster Model SS-3A – up to 300lbs – (1/2″ – 3/4″)

- Stainless Steel Stem Caster Model SS-G15 – up to 1500lbs – (3/4″ – 1″)

- Expanding Stem Casters

- Plate

- Pneumatic Casters

- Office Chair & Furniture Casters

- Find Casters by Industry (A-Z)

- Industries A-E

- Aerospace Industry Casters

- Automotive Industry Casters

- Automotive Jack Caster

- Bakery Casters

- Bellman Cart – Luggage Cart Brass Casters

- Butcher / Meat Handling Casters

- Black Finish / All Black E-Coat Casters

- Black Finish Casters / All Black E-Coat with Total Lock Brake

- Camper & Motor Home Casters

- CHAMBERS Oven | Vintage Oven Casters

- Convertible Hand Truck Casters

- Conveyor Casters

- Dairy Farm Casters

- Dolly Casters

- Door Casters

- Ergonomic Casters

- Expanding Stem Casters

- Industries F-J

- Industries K-O

- Industries P-T

- Pharmaceutical Casters

- Powder Coating & Media Blasting Casters

- Road Case Casters

- Rubbermaid Mop Bucket Casters

- Science and Animal Labs

- Shim Plates / Weld Plates

- Shop Fox Mobile Base Replacement Wheels

- Stainless Steel Casters for Metro and Nexus Racks

- Textile Casters

- Theatrical and Stage Casters for Scenery

- Toolbox Casters

- Turn Table Swivel / Lazy Susan

- Industries U-Z

- Industries A-E

- Wheel Only P/N’s

- Articles & How To Guides

- Shop

-

-

- TOTAL LOCKING CASTERS

Heavy duty casters

fsadfdsPlate casters

Stem casters

Gate Casters & Wheels: Reliable Solutions for Secure Gate Mobility

STAINLESS STEEL CASTERS

Stem

Plate

TOTAL LOCKING CASTERSTotal Locking CASTERS

Furniture CASTERS

Specific Industries

A

B

C

D

E

F

G

H-J

K

L

M

N-P

Q-R

S

T

Caster Wheels

Caster wheels are an essential component of many industrial and commercial applications, providing mobility and support for a wide range of equipment and machinery. They come in a variety of sizes, styles, and materials to suit specific needs and environments. Dual wheel casters offer a high load capacity and enhanced stability, making them ideal for moving heavy loads over rough or uneven terrain. Caster City’s casters are designed for light and heavy duty applications, withstanding constant use and harsh environments. They are manufactured using the highest quality materials and state-of-the-art processes, ensuring durability and reliability.

Replacement Caster Parts

Replacing caster parts is easy when you choose Caster City. They have a wide selection of replacement parts, ensuring you’ll find the right fit for your specific needs. Their knowledgeable customer service team is available to assist you in selecting the correct replacement parts and providing installation guidance. Caster City is committed to providing high-quality replacement parts that meet or exceed industry standards. They offer competitive pricing on their replacement caster parts, ensuring you get the best value for your money. Caster City prioritizes prompt order fulfillment, ensuring you receive your replacement parts quickly. With their extensive inventory, expert assistance, quality assurance, competitive pricing, and fast delivery, Caster City makes replacing caster parts a breeze.

-

-

- Plate Casters

-

-

Plate Casters by Plate Size

Plate Caster Model 3 – Up To 350lbs – 3″ thru 5″ Wheels – Plate Size 2-3/8″ x 3-5/8″

Capacity up to 350 pounds per caster. These casters are ideal for most types of equipment and projects where the total weight is less than 1000 lbs. on a set of 4 casters. They are offered with a wide selection of wheels. Model 3 casters are popular with retail business and consumer applications.

Mounting Plate & Sample Model 3 Casters

Available Add-Ons:

Plate Caster Model K3 – Up to 350 lbs – 3″ thru 5″ Wheels – Plate Size 3-1/8″ x 4-1/8″

Capacity up to 350 pounds per caster. These casters are ideal for most types of equipment and projects where the total weight is less than 1000 lbs. on a set of 4 casters. They are offered with a wide selection of wheels. Model K3 casters are popular with food service carts, office equipment, and stocking carts.

Mounting Plate & Sample Model K3 Casters

Available Add Ons:

Plate Caster Model 9 – Up To 1,200lbs – 3-1/4″ thru 8″ Wheels – Plate Size 4″ x 4-1/2″

Capacity up to 1200 pounds per caster. These rugged cold forged casters are recommended only for manually moved applications. Model 9 is our most popular industrial caster due to its widespread use throughout industry and its low initial cost. You should never select on the basis of load capacity alone. Capacity ratings do not take into account the effort required to manually move a load. Capacity ratings are based on manual operation under ideal conditions. Rollability is a function of floor surface, wheel material, capacity and the environment. If a human being has to move the weight, select the largest practical wheel diameter.Mounting Plate & Sample Model 9 Casters

Add On Options

Plate Caster Model G15 – Up To 2,000lbs – 4″ thru 8″ Wheels – Plate Size 4″ x 4-1/2″

Capacity up to 1200 pounds per caster. These rugged cold forged casters are recommended only for manually moved applications. Model 9 is our most popular industrial caster due to its widespread use throughout industry and its low initial cost. You should never select on the basis of load capacity alone. Capacity ratings do not take into account the effort required to manually move a load. Capacity ratings are based on manual operation under ideal conditions. Rollability is a function of floor surface, wheel material, capacity and the environment. If a human being has to move the weight, select the largest practical wheel diameter.Mounting Plate & Sample G15 Casters

Add On Options

The Long Lead Option is only available on the 6″ and 8″ Swivel Casters.

Plate Caster Model 30 – Up To 4,000lbs – 6″ thru 10″ Wheels – Plate Size 4-1/2″ x 6-1/4″

Capacity up to 4,000 pounds per caster. Model 30 features a large swivel and wheel bearing which allows for heavy loads and more arduous service. Model 30 has a precision machined swivel bearing, which provides superior performance on both manually moved and mechanically powered equipment. Benefits include easier swiveling, reduced swivel vibration, and longer trouble free performance.Mounting Plate & Sample Model 30 Casters

Add On Options:

Plate Caster Model 50 – Up To 7,000lbs – 6″ thru 12″ Wheels – Plate Size 5-1/4″ x 7-1/4″

Capacity up to 7,000 pounds per caster. Model 50 has a large top plate and thick legs, which allow for heavy loads and more arduous service. Model 50 has a precision machined swivel bearing, which provides superior performance on both manually moved and mechanically powered equipment. Benefits include easier swiveling, reduced swivel vibration, and longer trouble free performance. Suggested for a capacity of up to 7,000 lbs per caster in a manually moved application and for up to 6,000 lbs when moved with mechanically powered equipment. When used with mechanically powered equipment please consult us for a recommendation.Mounting Plate & Sample Model 50 Casters

Add On Options

Plate Caster Model 100 – Up To 15,000lbs – 6″ thru 12″ Wheels – Plate Size 6-1/4″ x 7-1/2″

Capacity up to 15,000 pounds per caster under ideal operating conditions.Load ratings are based on manually moved loads at a speed up to 3 mph under ideal operating conditions. If your application involves abuse please contact us for a recommendation. Consult us for a capacity rating based on your application if these casters are to be used with mechanically powered equipment. Model 100 has a large top plate and thick legs, which allow for heavy loads and more arduous service. Model 100 has a precision machined swivel bearing, which provides superior performance on both manually moved and mechanically powered equipment. Benefits include easier swiveling, reduced swivel vibration, and longer trouble free performance. When used with mechanically powered equipment please consult us for a recommendation.Mounting Plate & Sample Model 100 Casters

Add On Options

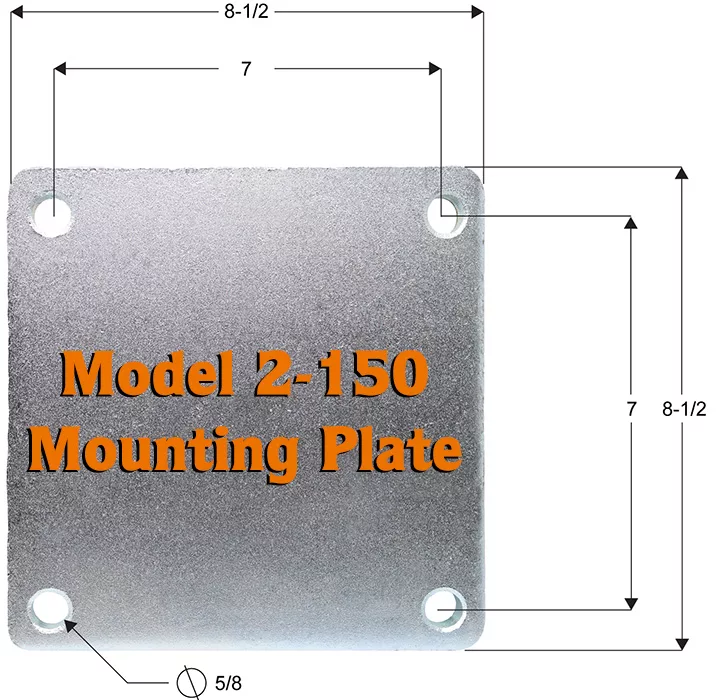

Plate Caster Model 150 – Up To 20,000 lbs – 8″ thru 12″ Wheels – Plate Size 8-1/2″ x 8-1/2″

Capacity 20,000 pounds per caster under ideal operating conditions. Load ratings are based on manually moved loads at a speed up to 3 mph under ideal operating conditions. If your application involves abuse please contact us for a recommendation. Consult us for a capacity rating based on your application if these casters are to be used with mechanically powered equipment. Model 150 has the largest top plate and thickest legs of any of our caster brackets which allow for the heaviest loads and the most arduous service. Model 150 has a precision machined swivel bearing, which provides superior performance on both manually moved and mechanically powered equipment. Benefits include easier swiveling, reduced swivel vibration, and longer trouble free performance. When used with mechanically powered equipment please consult us for a recommendation.Mounting Plate & Sample Model 150 Casters

Add On Options

Plate Caster Model 2-50 – Up To 7,000lbs – 6″ thru 12″ Wheels – Plate 5-1/4″ x 7-1/4″

Capacity up to 7,000 pounds per caster. Model 50 has a large top plate and thick legs, which allow for heavy loads and more arduous service. Model 50 has a precision machined swivel bearing, which provides superior performance on both manually moved and mechanically powered equipment. Benefits include easier swiveling, reduced swivel vibration, and longer trouble free performance. Suggested for a capacity of up to 7,000 lbs per caster in a manually moved application and for up to 6,000 lbs when moved with mechanically powered equipment. When used with mechanically powered equipment please consult us for a recommendation.Mounting Plate & Sample Model 2-50 Casters

Add On Options

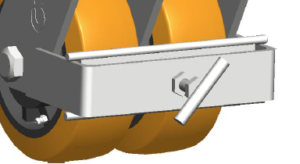

Plate Caster Model 2-100 – Up To 20,000lbs – 8″ thru 12″ Wheels – Plate 6-1/4″ x 7-1/2″

Dual Wheel casters provide a high load capacity with a minimum overall height. The larger footprint ( two wheels instead of one ) enhances stability and spreads the load over a larger floor area. The differential action inherent in all swivel dual wheel casters minimizes the effort required to change directions.Mounting Plate & Sample Model 2-100 Casters

Add On Options

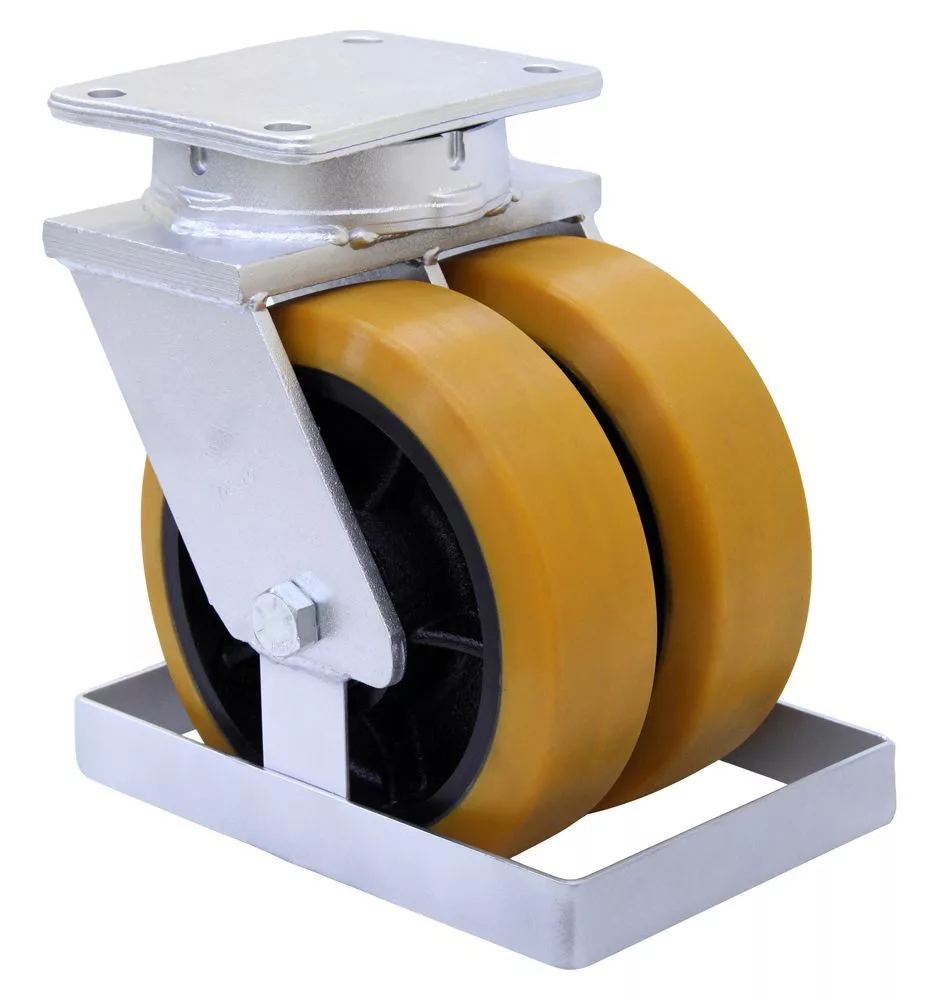

Plate Caster Model 2-150 – Up To 40,000lbs – 8″ thru 12″ Wheels – Plate 8-1/2″ x 8-1/2″

Dual Wheel casters provide a high load capacity with a minimum overall height. The larger footprint ( two wheels instead of one ) enhances stability and spreads the load over a larger floor area. The differential action inherent in all swivel dual wheel casters minimizes the effort required to change directions.

Our Dual Wheel casters are designed to offer a perfect blend of strength, stability, and ease of use. These casters are the perfect solution when you need to move heavy loads around your facility or worksite. With a high load capacity and a minimum overall height, these casters are suitable for a wide range of applications, including material handling, machinery, and equipment. Another benefit of dual wheel casters is their ability to handle rough or uneven terrain. The larger footprint and differential action make them ideal for use in outdoor or industrial environments where the ground may not be level or smooth. This can improve safety and efficiency by allowing workers to move heavy loads with greater ease and stability.

When it comes to casters that can withstand heavy loads, Caster City’s Model 2-150 is the go-to for many industries. Our casters are designed for that heavy load as well as for constant use and in harsh environments. We use only the highest-quality materials and state-of-the-art manufacturing processes to ensure that our products meet or exceed industry standards. We also offer competitive pricing and excellent customer service to ensure that you get the best value for your investment.

Mounting Plate & Sample Model 2-150 Casters

Add On Options

-

-

- Stem Casters

-

-

- Threaded Stem Casters (Diameter)Threaded Stem Casters (Diameter)

Expanding Rubber Stem

Size Chart:

Stem # ID of Tubing Rubber Range ( smallest size to largest size ) ER9 3/4″ .720″ to .851″ ER27 7/8″ .852″ to .927″ fits 1″ O.D. 16 or 18 Gauge ER28 1″ .928″ to 1.029″ ER7A 1 1/16″ 1.020″ to 1.100″ ER29 1 1/8″ 1.100″ to 1.180″ ER17 1 1/4″ 1.178″ to 1.303″ ER25 1 3/8″ 1.360″ to 1.425″ ER26 1 1/2″ 1.426″ to 1.589″ fits 1 5/8″ O.D. 16 or 18 Gauge ER21 1 13/16″ 1.790″ to 1.850″ Square & Round Metal Stem

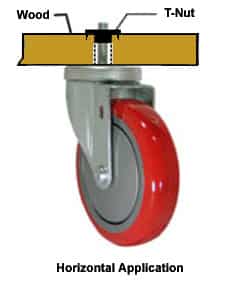

T-Nuts

T-Nuts can be used to secure our threaded stem casters to wooden items. Here we show the typical use of the T-Nut for both a Horizontal and a Vertical Application.

In the Horizontal Application, you would drill a hole equal to the diameter of the barrel of the T-Nut and completely thru your wood. Hammer the T-Nut into the hole and thread your caster in from the bottom. This is the strongest mounting.

The Vertical Application is for attaching casters to the bottom of legs and into the end grain of the wood. This is not an exceptionally strong way to mount! Drill your hole equal to the diameter of the barrel of the T-Nut and to the depth of the length of the stem of the caster plus about 1/4″. Apply 2 part epoxy to the T-Nut for additional strength. Hammer the T-Nut into the hole and thread your caster in from the bottom. You must use epoxy as we have had problems with some woods where the nuts ( and the casters ) fall off.

-

-

- Total Locking Brake Casters

-

-

Total Locking Plate Casters

Total Locking Stem Casters Information

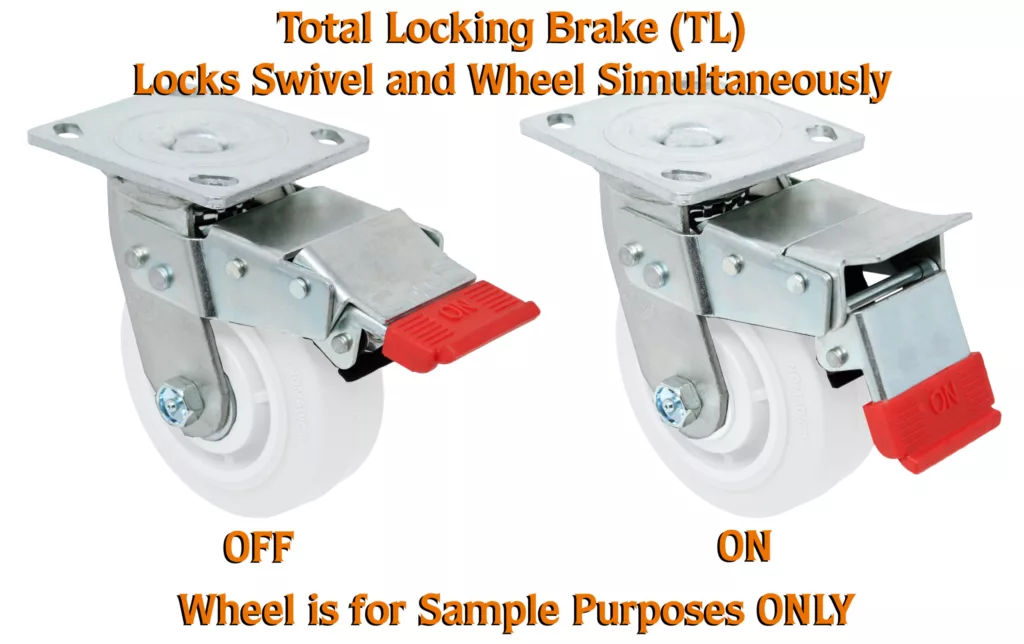

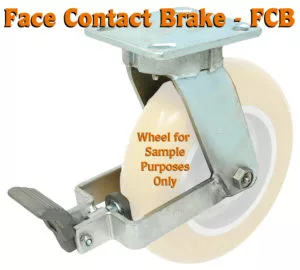

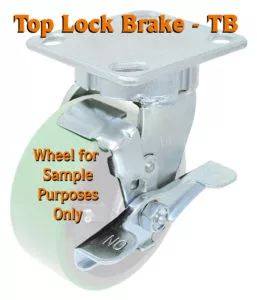

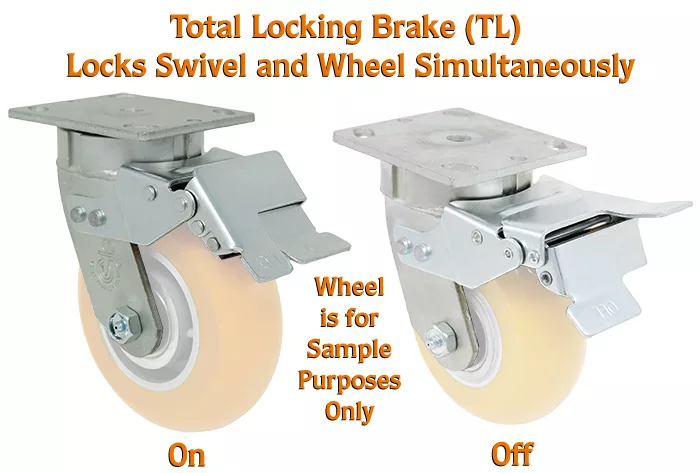

Total Locking Casters are defined by their brake, which locks the swivel bearing and wheel at the same time. On this page we show both nylon and metal pedal style total locking stem casters. These are modular stem casters, meaning any stem can be assembled to your preferred caster style to fit your needs.

Metal Pedal Total Locking Stem Caster – Model 3A and Stainless Steel Model 3A

-

-

- Stainless Steel Casters

-

-

- Stainless Steel Plate CastersStainless Steel Stem CastersStainless Steel Plate Casters

Stainless Steel PLATE Casters

UP TO 300LBS – 3″ THRU 5″ WHEELS –

PLATE SIZE 2-3/8″ X 3-5/8″UP TO 900LBS – 4″ THRU 8″ WHEELS –

PLATE SIZE 4″ X 4-1/2″UP TO 1500LBS – 4″ THRU 8″ WHEELS –

PLATE SIZE 4″ X 4-1/2″UP TO 3000LBS – PLATE SIZE 4-1/2″ X 6-1/4″

UP TO 3000LBS – PLATE SIZE 5-1/4″ X 7-1/4″

STAINLESS STEEL KINGPINLESS CASTERS

Stainless Steel Stem CastersStainless Steel Stem Casters

UP TO 300LBS – (1/2″ – 3/4″)

up to 1500lbs – (3/4″ – 1″)

Expanding

-

-

- Pneumatic Casters

-

-

Pneumatic Caster Wheels

These industrial pneumatic casters feature air filled pneumatic wheels. These industrial casters are designed for low speed manually moved applications only. Air filled pneumatic wheels provide a cushioned ride, shock absorption and quiet operation. Pneumatic casters are ideally suited for moving fragile or delicate cargo where caster overall height is not critical. Casters with pneumatic wheels are usually the best choice for use outdoors over rough surfaces ( i.e. gravel ) or on grass. The wide footprint on 8″ or larger pneumatic wheels provides stability on gravel and does not sink into lawns.

Pneumatic casters and pneumatic wheels are also popular for indoor use in places such as hospitals, scientific and electronic laboratories, hotels, department stores and TV or movie studios.

Pneumatic wheels with black tires do not mark the floor as long as the wheel is allowed to roll. Changing directions without allowing a swivel caster to turn gradually around, or dragging a black rubber wheel sideways, can mark some floors.

Light Duty Flat Free Casters

Capacity up to 150 pounds per caster. Popular for use in places such as hospitals, scientific and electronic laboratories, hotels, department stores and TV or movie studios. Not recommended for use while moving with a camera.

Capacity up to 150 pounds per caster. Popular for use in places such as hospitals, scientific and electronic laboratories, hotels, department stores and TV or movie studios. Not recommended for use while moving with a camera.Pneumatic Caster Alternatives

Casters with Super Cushion Rubber Wheels

Casters with Semi-Pneumatic Wheels

Foam Filled Pneumatic Casters

These industrial casters are designed for low speed manually moved applications only. Foam Filled Pneumatic Wheels have NO air in the tires, thus eliminating the possibility of the wheels ever going flat.

Foam Filled wheels do NOT have any resilience. They provide the same traction and wide footprint of air filled wheels which enables them to roll on grass, dirt and over small pebbles.

Foam Filled Pneumatic Wheels have a higher initial cost than Air Filled Pneumatic Wheels. However, over time, they may prove to cost less because they last longer and avoid down time due to loss of air. Since people tend to load equipment only to the weight they can move easily,

Foam Filled Pneumatic Wheels can lead to higher productivity because they require less effort to move than pneumatics that are under inflated.

-

-

- Office Chair & Furniture Casters

-

-

CHAIR AND FURNITURE CASTERS FOR CARPET

We do not recommend any wheel to roll on soft wood, cork, or hard wood with a rating below 1360 on the Janka Scale. Chair casters with soft rubber wheels provide the best floor protection for hard wood floors. “Engineered” hard wood flooring has a thin wood veneer bonded to a substrate material. We recommend that the hard wood veneer be at least 1/4″ thick if the caster wheel is soft rubber, and 1/2″ thick if the caster wheel is polyurethane. We advise that you consult with the manufacturer of the flooring before using casters on their product. We can not guarantee that the substrate of “Engineered” flooring will not compress. All that we warranty is the construction and quality of our chair casters. Hooded Twin Wheel Casters with Polyurethane Tires is available with 50mm polyurethane wheels. This caster will work well on either hard floor surfaces or short pile carpet

We do not recommend any wheel to roll on soft wood, cork, or hard wood with a rating below 1360 on the Janka Scale. Chair casters with soft rubber wheels provide the best floor protection for hard wood floors. “Engineered” hard wood flooring has a thin wood veneer bonded to a substrate material. We recommend that the hard wood veneer be at least 1/4″ thick if the caster wheel is soft rubber, and 1/2″ thick if the caster wheel is polyurethane. We advise that you consult with the manufacturer of the flooring before using casters on their product. We can not guarantee that the substrate of “Engineered” flooring will not compress. All that we warranty is the construction and quality of our chair casters. Hooded Twin Wheel Casters with Polyurethane Tires is available with 50mm polyurethane wheels. This caster will work well on either hard floor surfaces or short pile carpetSoft Gray Rubber Chair Casters for Work From Home Life

Our Elite Series Chrome Chair Casters offers soft ray rubber wheels which can not mark or damage hardwood floors. The soft rubber wheel is available in both 2″ and 3″ diameters. Although we do not recommend any caster for a SOFT WOOD floor such as Pine, the Elite series with it’s extra soft rubber wheels has been used successfully on SOFT WOOD floors.

Chair Casters for Hardwood Floors

These chair casters are for use on Hardwood or ANY hard floor surface. Many home owners and businesses are tearing out carpeting and installing wood floors. To protect these floors you need to use a soft wheel. Although most recommendations are for a soft rubber wheel on hardwood, a soft polyurethane caster wheel can also be used on hardwood floors.

Most of the office chairs that are manufactured today come with twin wheel nylon casters. This type of caster, specifically the nylon wheel, can be used on carpeting but it will mark and scratch all wood floors. It happens because the nylon wheels don’t roll, they slide. When they slide, they mark or scratch the floor. Our selection of hard wood chair casters is the ideal solution for this problem. The soft rubber wheels on our chair casters for hardwood floors will not mark or scratch the floors.

The Chrome Caster, our Elite series, offers both soft rubber wheels for hardwood floors and a stylish polyurethane wheel which can be used on either hardwood floors or carpeting. The soft rubber wheel is available in both 2″ and 3″ diameters. Although we do not recommend any caster for a SOFT WOOD floor such as Pine, the Elite series with it’s extra soft rubber wheels has been used successfully on SOFT WOOD floors.

Chair Casters for Doctor and Dentist Office

These chair casters are for use on Hardwood or ANY hard floor surface.

Most of the office chairs that are manufactured today come with twin wheel nylon casters. This type of caster, specifically the nylon wheel, can be used on carpeting but it will mark and scratch all wood floors. It happens because the nylon wheels don’t roll, they slide. When they slide, they mark or scratch the floor. Our selection of medical casters for doctor and dental office chair casters are the ideal solution for this problem. The soft rubber wheels on our chair casters for hardwood floors will not mark or scratch the floors.

Elite Chair Casters for Gaming Chairs

Our Elite Series Chrome Chair Casters offers soft ray rubber wheels which can not mark or damage hardwood floors. The soft rubber wheel is available in both 2″ and 3″ diameters. Although we do not recommend any caster for a SOFT WOOD floor such as Pine, the Elite series with it’s extra soft rubber wheels has been used successfully on SOFT WOOD floors.

Our Elite Series Chrome Chair Casters offers soft ray rubber wheels which can not mark or damage hardwood floors. The soft rubber wheel is available in both 2″ and 3″ diameters. Although we do not recommend any caster for a SOFT WOOD floor such as Pine, the Elite series with it’s extra soft rubber wheels has been used successfully on SOFT WOOD floors.SOCKETS FOR CASTERS

These hard to find sockets are now available for purchase separately. Sockets may be returned for exchange only, please measure carefully.

-

-

- Find Casters by Industry (A-Z)

-

-

INDUSTRIES A-E

INDUSTRIES K-O

INDUSTRIES P-T

-

-

- Wheel Only P/N’s

-

-

High Temperature Caster Wheels

The High Temperature Phenolic Wheels ( prefix “TP” ) , the High Temperature Glass-Filled Nylon wheels ( prefix “NP” ), and the High Temperture “OV” Epoxy Resin Wheels have a hard surface and should be used on smooth floor surfaces. If the floors are rough or if there are obstructions which will impact these wheels it will reduce the service life of the wheels. In any high temperature application it is always best to shield High Temperature Wheels from a direct heat intake source. Consult us for a load capacity rating in your application. We will need the following information: Maximum Temperature and for how long? Maximum load on each caster? Is your application wet or dry?

Phenolic Caster Wheels

Phenolic caster wheels are made from macerated canvas mixed with phenolic resin, and molded under high pressure and temperature. Its hardness is comparable to polished maple flooring. Phenolic caster wheels are recommended for smooth concrete and can be used for storage (standing) loads without permanent set. These caster wheels are highly resistant to oil, grease, gasoline and mild acids. It is not recommended for wet applications where the wheel will be in standing water. They are affected in various degrees by strong acids and some alkaline solutions. Temperature range is -40° to +250° F, with intermittent use up to 300° F. Phenolic caster wheels will carry loads as great as the same size iron wheel. The wheel material may chip or cut from contact with steel plate or from rolling over steel parts on the floor. The wheel tread may show wear from repeated travel over rough surfaces. Floor wear is slight except where floors are already starting to deteriorate. These wheels can be made with a laminated unmacerated tread to provide 25% more capacity and greater chip resistance.

Ultra High Capacity Polymer Caster Wheels

These wheels provide high load capacity without causing floor wear associated with metal wheels. Unlike polyurethane wheels, there is no risk of flat spots or delamination if these wheels are left parked for a prolonged period. Instead of injection molding, these wheels are compression molded and then machined. Their straight sided shape maximizes load capacity.

V Groove Caster Wheels

V-groove caster wheels are designed to guide equipment by rolling on inverted angle iron track. Elevated track minimizes problems caused by floor debris. The relief groove at the base of the “V” equalizes the load on each face of the angle. Forged Steel V-groove caster wheels minimize wear of the V-groove sides and are best for frequent operation. When not operating on track, the considerable wheel tread on each side of the V-groove allows for use on smooth floors. It is important that if more than one track is used they are parallel, straight and level. Otherwise V-groove wheels may bind or run up over the track. Tolerance should be within plus or minus 1/64″ every 20 feet. Joints between pieces of track should be smooth and well reinforced. V-groove caster wheels are standard with straight roller bearings, which allow only 1/16″ total end play (side to side movement). It is desirable when loads are great to use tapered bearings, which have thrust as well as radial capacity. The proper adjustment of tapered bearings prohibits end play. Compression must be applied to properly seat tapered bearings. This is achieved by tightening down against a bearing spacer on each side of the wheel to a maximum looseness of .010. Since tapered bearings prohibit end play, their use requires parallel track. Unless the layout is nearly perfect, it is best to use a single angle iron track for V-groove caster wheels parallel to an elevated flat bed for wheels without a V-groove.

Nylon Caster Wheels

White Nylon Caster Wheels are made with a solid nylon material. Black Nylon Caster Wheels are reinforced with glass fiber to increase capacity and reduce friction when rolling.

These wheels weigh very little yet they have a load capacity comparable to most metal wheels. They will not develop a flat spot. Nylon wheels are a better choice in wet and corrosive applications which require both chemical resistance and a higher load capacity.

Not recommended if the acid content exceeds 10% of your solution.

RUBBER CASTER WHEELS

These caster wheels have non-marking injection molded thermoplastic rubber tires mechanically bonded to a polyolefin ( industrial plastic ) center. They are popular on equipment in Pharmaceutical Laboratories, Hospitals, Food Service and other Institutional applications. These caster wheels provide a softer ride than polyurethane and yet withstand exposure to many chemicals and solvents. They can be used in industrial applications which do not involve shock, overloading, abuse, obstructions, poor floors or storage (standing) loads. Wheels with RH prefix have a slightly higher capacity than our other gray soft rubber wheels.

POLYURETHANE

Polyurethane caster wheels are non marking and non conductive. The absence of a metal center eliminates bond failure as a cause for wheel replacement. These caster wheels are especially suited for use with stainless steel casters in wet and corrosive applications.

They are designed for use in Pharmaceutical Laboratories, Hospitals, and Food Processing Plants – wherever a clean sanitary design is desired. These wheels are not recommended for applications involving shock, overloading, abuse, obstructions, poor floors, or for storage (standing) loads. Hardness is 60 – 65 Durometer Shore D. Temperature range is -20° to 180° F. Standard wheel color is Blue.

These wheels are designed for use in a wet environment and they eliminate the possibility of tire separation.

Caster Wheels

Caster wheels are an essential component of many industrial and commercial applications, providing mobility and support for a wide range of equipment and machinery. They come in a variety of sizes, styles, and materials to suit specific needs and environments. Dual wheel casters offer a high load capacity and enhanced stability, making them ideal for moving heavy loads over rough or uneven terrain. Caster City’s casters are designed for light and heavy duty applications, withstanding constant use and harsh environments. They are manufactured using the highest quality materials and state-of-the-art processes, ensuring durability and reliability.

Polyolefin Caster Wheels

Polyolefin Caster Wheels are injection molded from a blend of thermoplastic polymers forming a one piece solid sanitary design. These Polyolefin wheels, as with Nylon wheels, are especially suited for wet and corrosive applications. They are very resistant to most commonly encountered liquids. Polyolefin wheels have a lower capacity and a more limited temperature range than Nylon wheels with the exception of our Extra Heavy Duty Polyolefin wheels ( prefix RK ). In a cold dry environment, such as a refrigerated store room, Polyolefin wheels may become brittle. They should not be used in a freezer or a heat application above 180°F intermittent usage, such as a rack washer.

Our Extra Heavy Duty Polyolefin Caster Wheels ( prefix RK in the part number ) are reinforced with glass fiber to increase capacity and temperature range. These Extra Heavy Polyolefin wheels are comparable to Nylon wheels in load capacity. They are also especially suited for wet and corrosive applications. Extra Heavy Duty Polyolefin wheels are standard with Non-Stainless Precision Sealed Ball Bearings ( PS ) and Stainless Precision Sealed Ball Bearings ( SPS ).

Not recommended if the acid content exceeds 10% of your solution.

Replacement Caster Parts

Replacing caster parts is easy when you choose Caster City. They have a wide selection of replacement parts, ensuring you’ll find the right fit for your specific needs. Their knowledgeable customer service team is available to assist you in selecting the correct replacement parts and providing installation guidance. Caster City is committed to providing high-quality replacement parts that meet or exceed industry standards. They offer competitive pricing on their replacement caster parts, ensuring you get the best value for your money. Caster City prioritizes prompt order fulfillment, ensuring you receive your replacement parts quickly. With their extensive inventory, expert assistance, quality assurance, competitive pricing, and fast delivery, Caster City makes replacing caster parts a breeze.

-

-

- Articles & How To Guides

Gray Iron Caster Wheels

- Home

- Gray Iron Caster Wheels

©2003 - 2023 castercity.com®.

The words "Caster City" and the Caster City Logos are Registered Trademarks.”

The words "Caster City" and the Caster City Logos are Registered Trademarks.”